Апаратура дистанційного контролю рухомих одиниць АКРО

АКРО – комплексне рішення для інтелектуальної діагностики та моніторингу рухомого складу

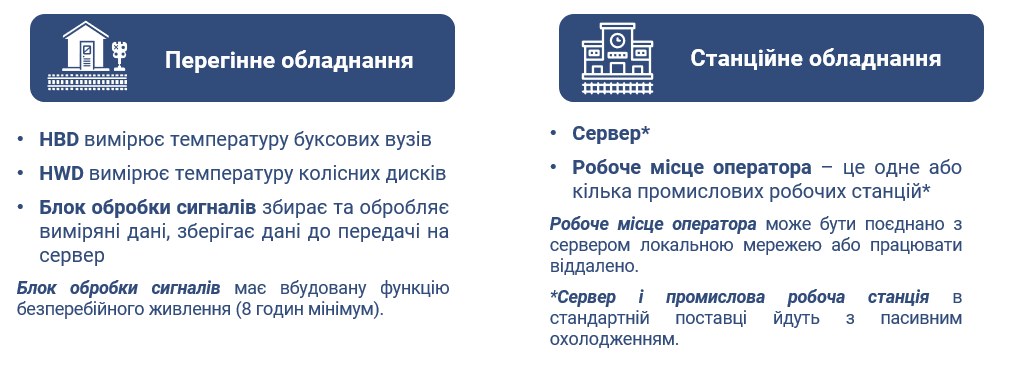

- Модульне обладнання (перегінне та станційне) для діагностики

- Гнучка та багаторівнева система централізації для моніторингу

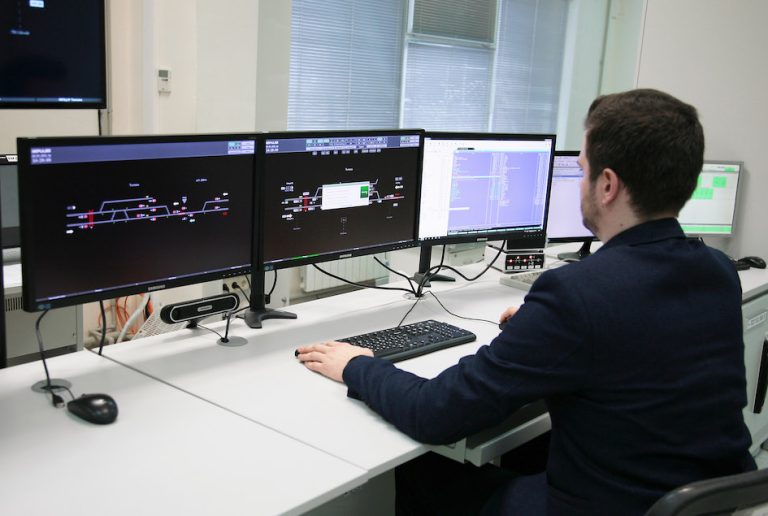

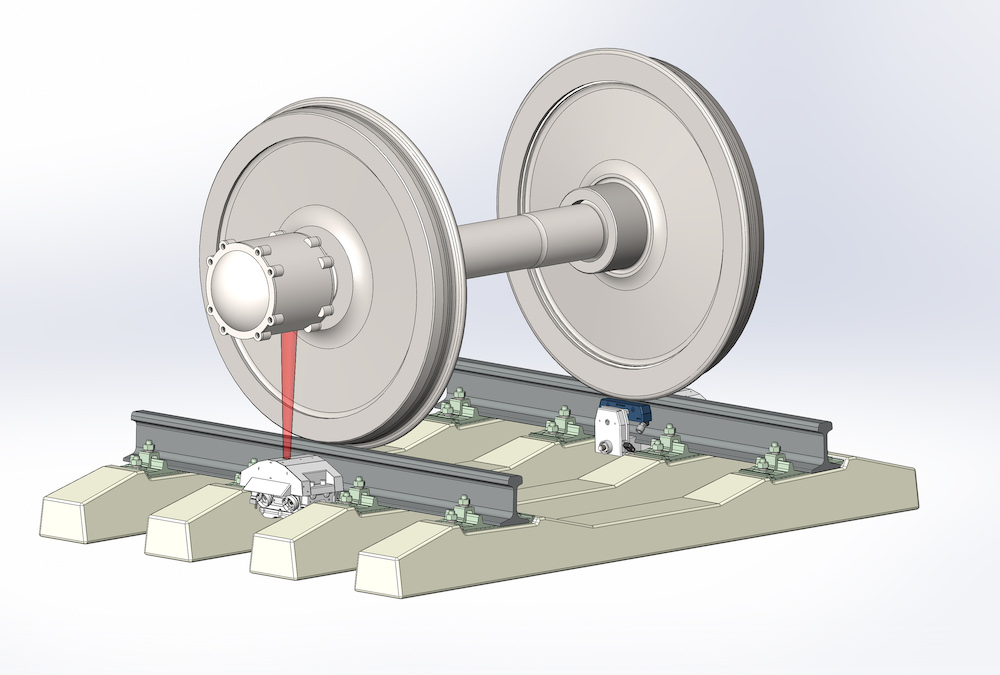

HBD – Виявлення перегрітих буксових вузлів (Hot Box Detection)

HWD – Виявлення загальмованих колісних пар (Hot Wheel Detection)

DED – Виявлення предметів, що волочаться (Dragging Equipment Detection)

AVI – Автоматична ідентифікація рухомого складу (Automatic Vehicle Identification)

WDD – Виявлення дефектів коліс (Wheel Defect Detection)

WIM – Зважування в русі (Weighing In Motion)

Базові функції АКРО

Функція виявлення перегрітих буксових вузлів (HBD) використовується для виявлення нагріву буксових вузлів через вихід з ладу підшипників.

Дефекти підшипників та несправності гальмівної системи є найпоширенішими поломками рухомого складу. Дефекти підшипників є дійсно небезпечними через швидке погіршення якостей колісної пари, що може призвести до зламу шийки осі та сходження поїзда з рейок.

Економічні втрати від подібних інцидентів можуть сягати мільйонів Євро.

Функція виявлення загальмованих колісних пар (HWD) використовується для виявлення нагріву колісних дисків через заклинення гальмівних колодок.

Ще однією частою поломкою рухомого складу є вихід з ладу гальмівної системи (заклинювання і спрацювання колодок). При заклинюванні гальмівних колодок вони швидко зношуються, збільшуються витрати палива/енергії на тягу. В окремих випадках значне нагрівання диску колеса може бути пожежонебезпечним.

АКРО дозволяє виміряти температуру в районі реборд–зони, що найбільше нагрівається при заклинюванні гальм.

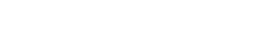

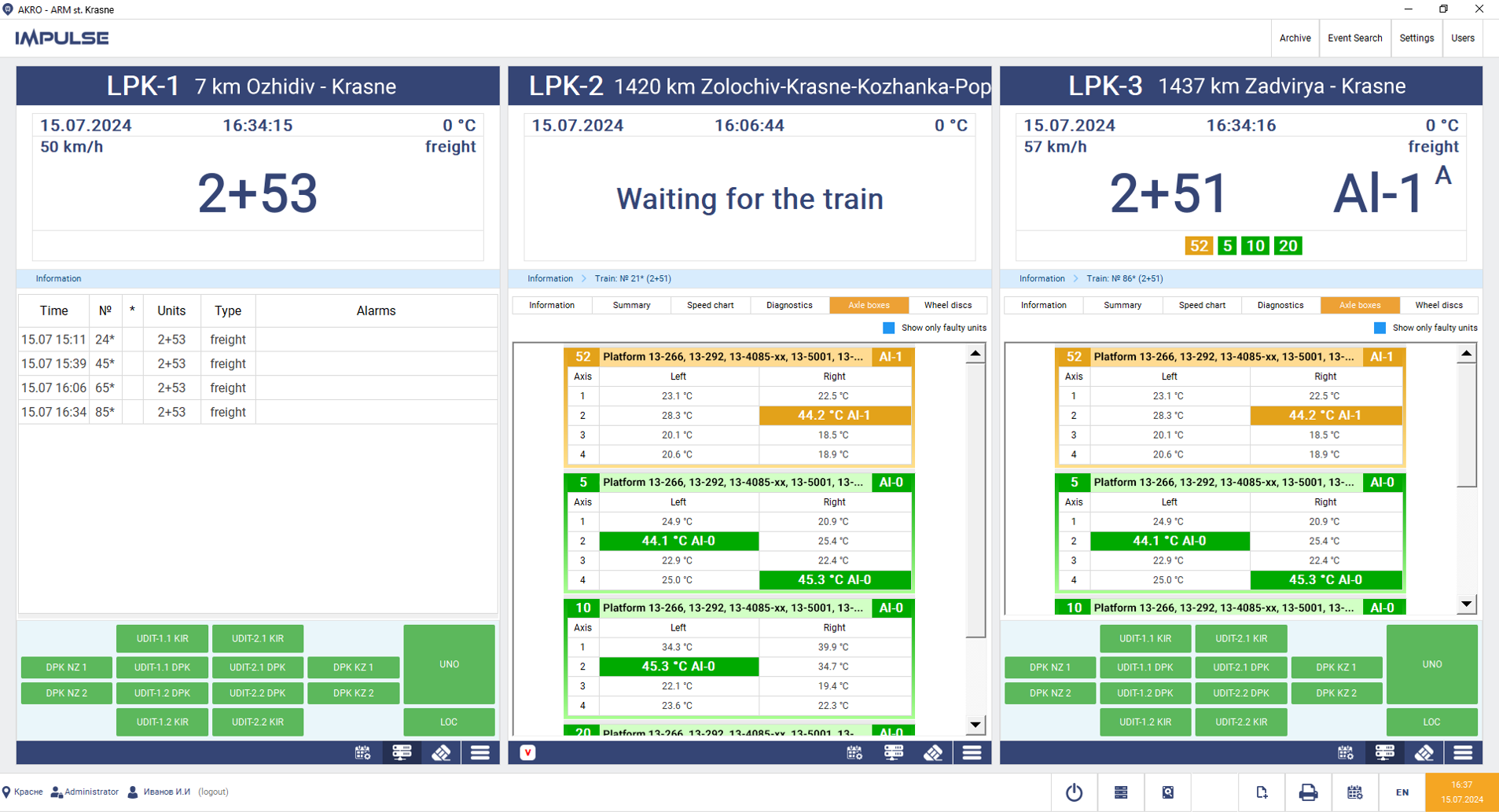

Програмне забезпечення АКРО-Б

АКРО-Б дозволяє оператору отримати:

- Інформацію про поїзди (у режимі реального часу та минулих раніше)

- Інформацію про статус обладнання пунктів контролю

Можливість перегляду всіх виміряних температурних профілів (буксові вузли і колеса).

Температурні профілі об’єднують дані про температуру і сигнали датчиків проходу коліс. Це суміщення дозволяє швидко і адекватно оцінити первинні дані вимірювань за необхідності.

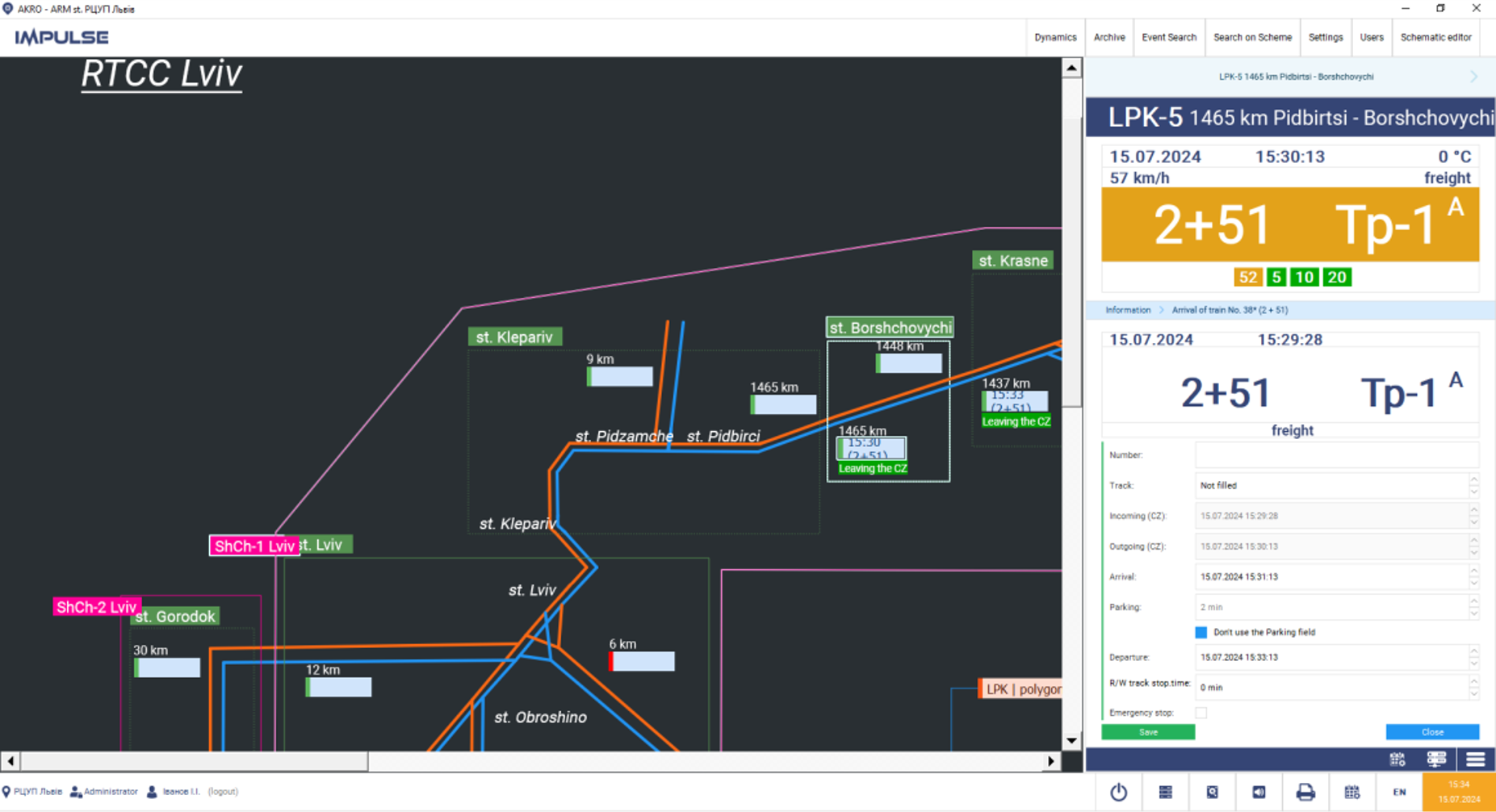

Програмне забезпечення АКРО-Ц. Централізація

Оперативна інформація про ситуацію, сповіщення про попередження та тривоги:

- Інформація про стан рухомих одиниць у складі поїздів, що пройшли через пункти контролю

- Деталізація попереджень та тривог кожного проходу поїзда

- Інша інформація про проходи поїзда

Доступ до детальної інформації про стан поїзда та обладнання АКРО на лінійних пунктах контролю:

Дата і час проходження

Кількість рухомого складу/осей

Попередження та тривоги

Стан перегінного обладнання АКРО

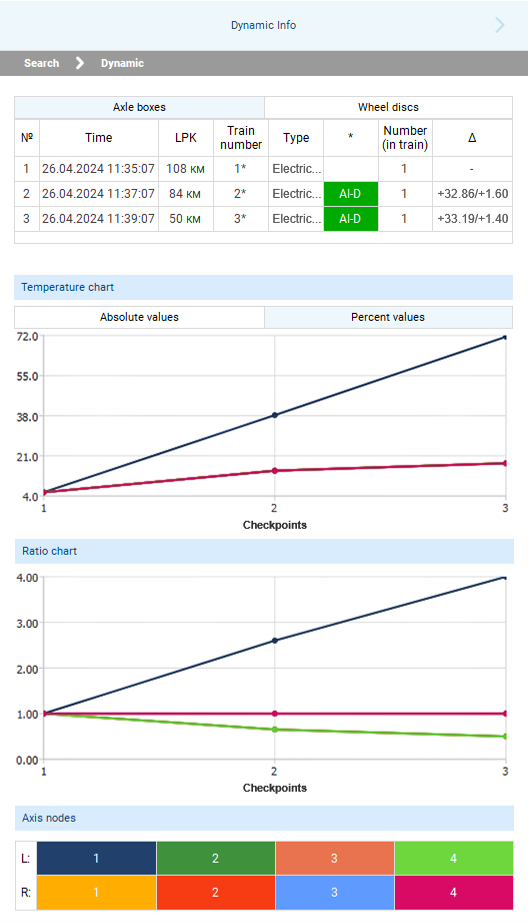

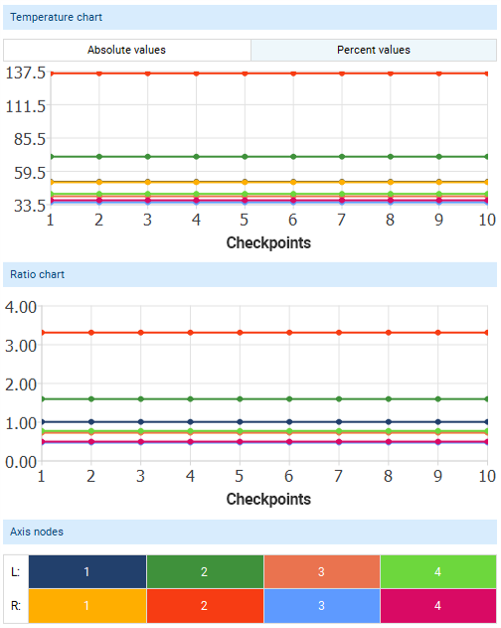

Моніторинг зміни стану рухомого складу в динаміці:

- Автоматизований аналіз нагріву буксових вузлів

- Автоматизований аналіз нагріву коліс

- Автоматизований аналіз інших параметрів (програмується)

Дозволяє візуалізувати у вигляді графіків зміну температури в абсолютних значеннях, процентах та коефіцієнтах