Комплексна система діагностики обладнання першого контуру реакторної установки

Функції КСД:

- Поглиблене комплексне технічне діагностування основного обладнання першого контуру РУ шляхом зіставлення та аналізу діагностичної інформації, отриманої від систем контролю та управління енергоблоку, локальних систем діагностики та власних баз даних;

- Забезпечення централізованого доступу інженера-діагноста до оперативної та архівної діагностичної інформації, що надходить від різних джерел (ІОС, АСРК та ін.) та дозволяє визначати та прогнозувати технічний стан експлуатованого обладнання першого контуру РУ;

- Передача до локальної обчислювальної мережі енергоблоку параметрів для надання персоналу.

Склад КСД:

- Система верхнього рівня КСД;

- Система віброшумової діагностики СВРШД;

- Система виявлення вільних та слабозакріплених предметів СОСП;

- Система контролю протікання теплоносія першого контуру СКПТ;

- Система віброконтролю та діагностики головних циркуляційних насосів СВКД ГЦН;

- Система діагностування залишкового ресурсу обладнання реактора СДЗР;

- Система контролю переміщення трубопроводів СКПТр.

Система віброшумової діагностики СВРШД

Система призначена для моніторингу та діагностування вібраційного стану обладнання першого контуру, контролю:

- Траєкторії теплового переміщення основного обладнання першого контуру в режимах розігріву-розхолодження для виявлення непроєктних траєкторій переміщень, спричинених дефектами опор контрольованого обладнання;

- Вібраційного стану основного обладнання першого контуру, включно з корпусом реактора, з метою виявлення аномальних вібрацій, викликаних зміною жорсткісних характеристик опор, ослабленням вузлів кріплення обладнання або зростанням сил, що спричинюють вібрацію;

- Вібраційного стану ТВС з метою виявлення аномальних вібрацій, викликаних ослабленням вузлів кріплення або зростанням впливу з боку теплоносія;

- Вібраційного стану шахти реактора з метою виявлення аномальних вібрацій, спричинених зносом вузлів кріплення або збільшеним впливом з боку теплоносія.

Функції СВРШД:

- Введення, перетворення та порівняння з уставками сигналів від датчиків вібрації, вібропереміщення, блоків детектування нейтронів і датчиків прямого заряду;

- Прийом інформації про технологічні параметри реактора від ІОС енергоблоку;

- Архівування даних моніторингу та діагностики;

- Розрахункове діагностування вібраційного стану з урахуванням поточних та архівних даних, формування звітів;

- Передача в обчислювальний сервер КСД інформації про стан обладнання, що діагностується.

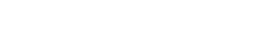

Система виявлення вільних та слабозакріплених предметів СОСП

Система призначена для раннього виявлення та визначення місця знаходження в потоці теплоносія предметів, що вільно переміщаються, і деталей обладнання з ослабленим кріпленням з використанням акустичних датчиків, встановлених на поверхні обладнання першого контуру реактора.

Функції СОСП:

- Введення, перетворення та порівняння з уставками шумових сигналів від акустичних датчиків;

- Контроль корпусного шуму основного обладнання та трубопроводів першого контуру, визначення наявності в потоці теплоносія вільних та слабозакріплених предметів;

- Архівування даних, прослуховування та запис акустичних сигналів;

- Контроль працездатності каналів прийому та обробки сигналів датчиків;

- Надання результатів діагностування оператору та передача в обчислювальний сервер КСД.

Система контролю протікання теплоносія першого контуру СКПТ

Система призначена для контролю герметичності обладнання та трубопроводів головного циркуляційного контуру, своєчасного виявлення місця течі теплоносія першого контуру, оцінки її величини в режимах нормальної експлуатації, з порушеннями нормальної експлуатації та в режимі «мала теча».

Функції СКПТ:

- Введення, перетворення та порівняння з уставками сигналів від датчиків вологості та температури, акустичних датчиків;

- Прийом інформації від інформаційно-обчислювальної системи енергоблоку;

- Комплексний аналіз з визначення місця та величини течі;

- Передача результатів діагностування в обчислювальний сервер КСД та оператору;

- Формування попереджувальної сигналізації.

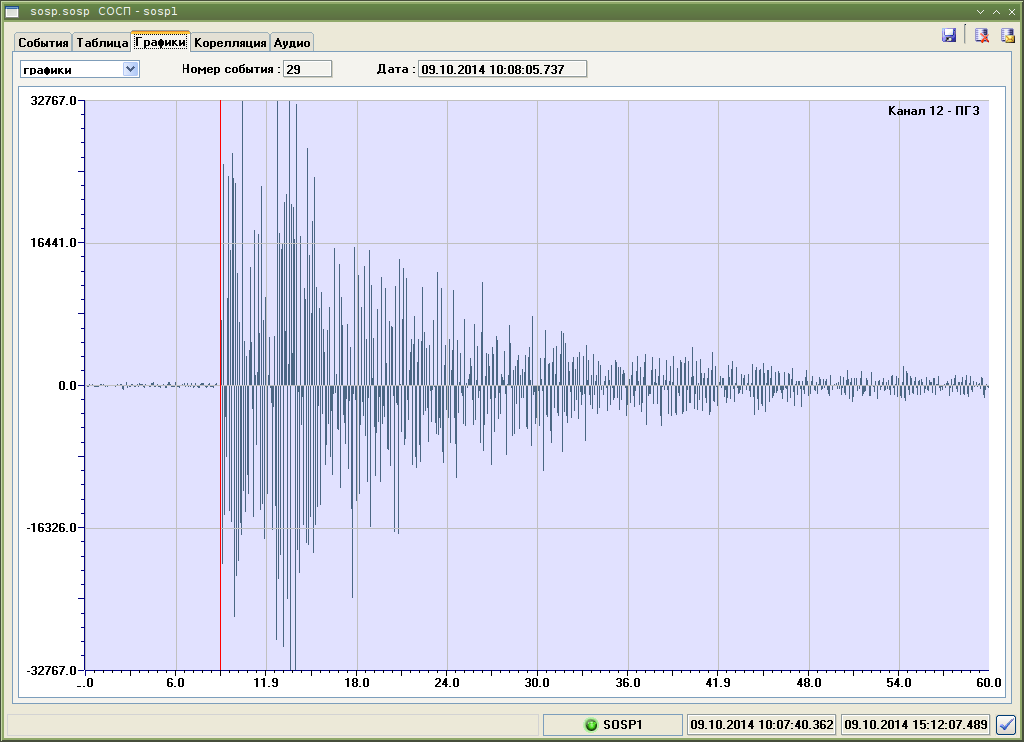

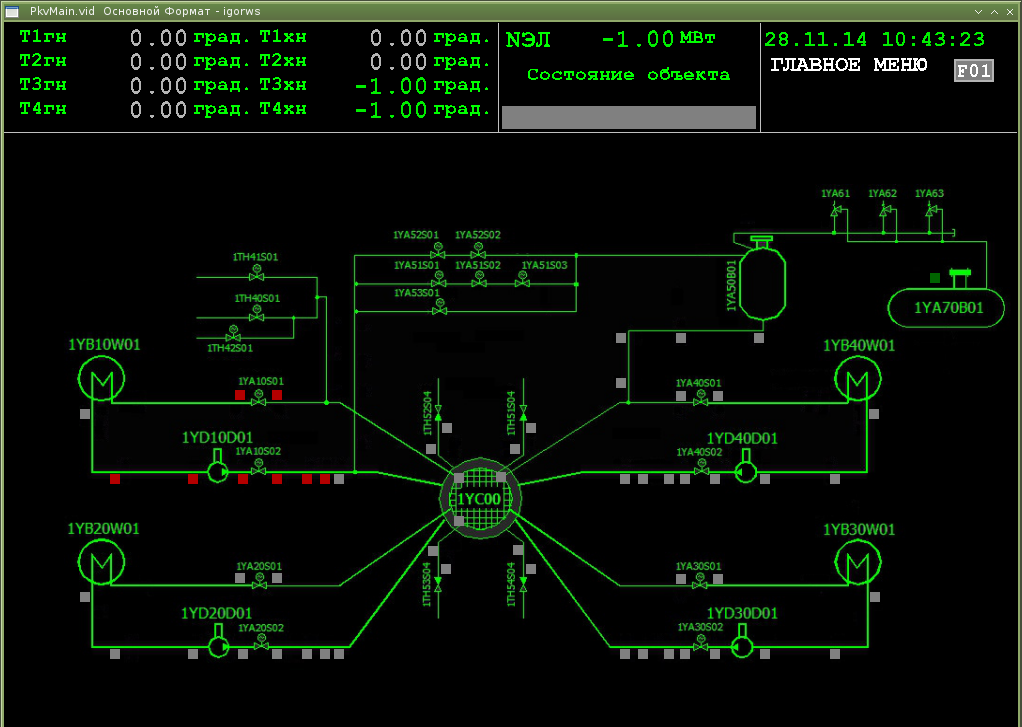

Система віброконтролю та діагностики головних циркуляційних насосів СВКД ГЦН

Система призначена для моніторингу вібраційних параметрів ГЦН з метою раннього виявлення аномальних станів механічної та електричної частини, прогнозування технічного стану на підставі комплексного аналізу вібраційних характеристик та теплотехнічних параметрів.

Функції СВКД ГЦН:

- Безперервний контроль вібраційного стану ГЦН та ідентифікація дефектів, що повільно розвиваються;

- Контроль вібраційних характеристик у різних режимах роботи ГЦН, включно з режимом вибігу ротора за відключення живлення електродвигуна;

- Аналіз, архівування та протоколювання даних;

- Діагностика стану ГЦН з наданням результатів інженеру-діагносту та формуванням сигналізації.

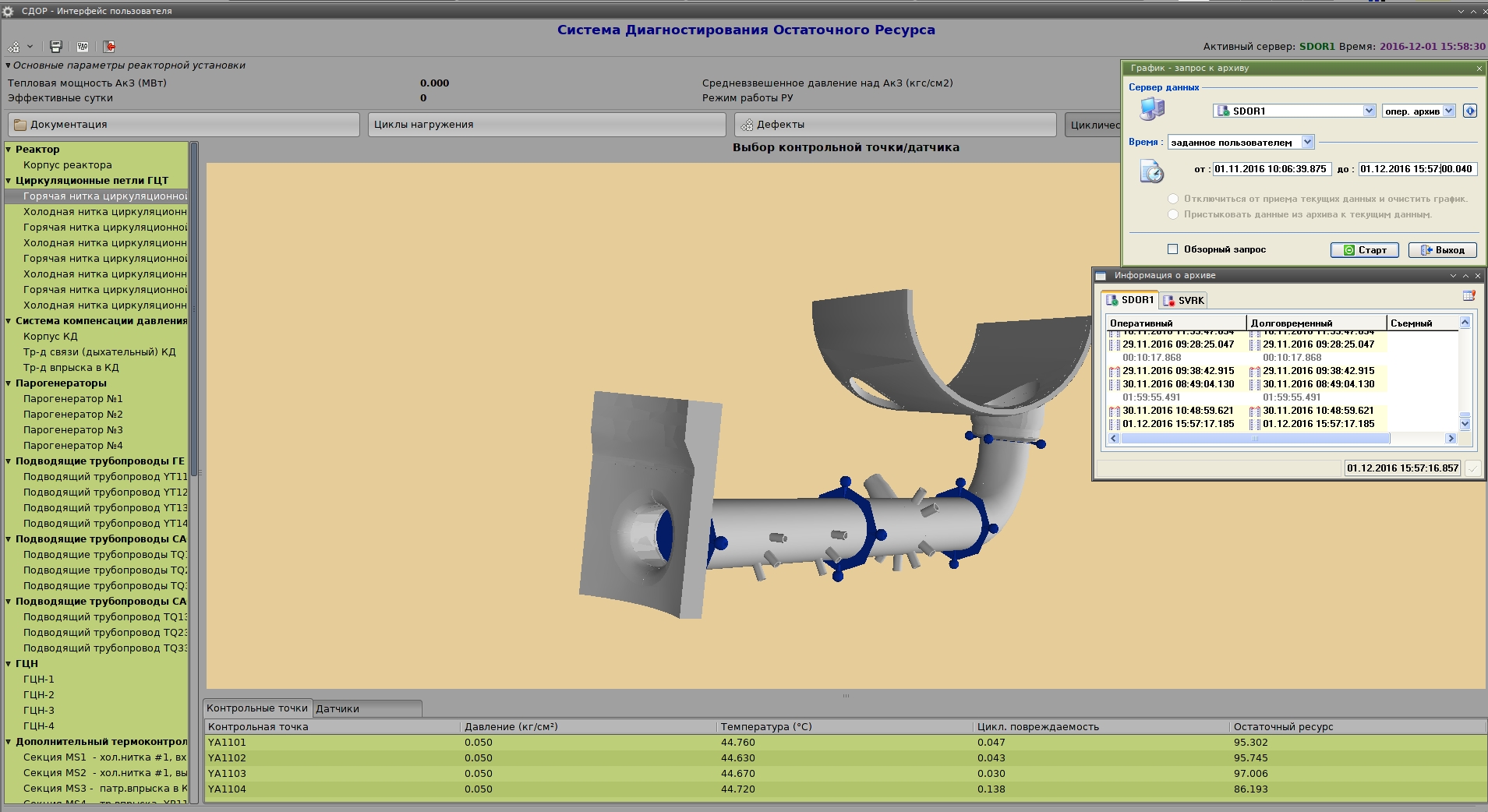

Система діагностування залишкового ресурсу СДЗР

Система призначена для розрахунку накопиченого втомного пошкодження металу в найбільш напружених точках конструкції та оцінки залишкового ресурсу елементів основного обладнання першого контуру реактора на основі безперервного контролю теплотехнічних параметрів у різних режимах експлуатації.

Функції СДЗР:

- Введення та перетворення сигналів від датчиків термоконтролю (контроль термопульсацій та стратифікації теплоносія), прийом інформації від обчислювального сервера КСД;

- Розрахунок втомного пошкодження та залишкового ресурсу в контрольних (найбільш навантажених) точках;

- Оцінка залишкового ресурсу металу обладнання та трубопроводів;

- Ведення баз даних, реєстрація сигналів, отриманих від ІОС, КСД та власних датчиків.

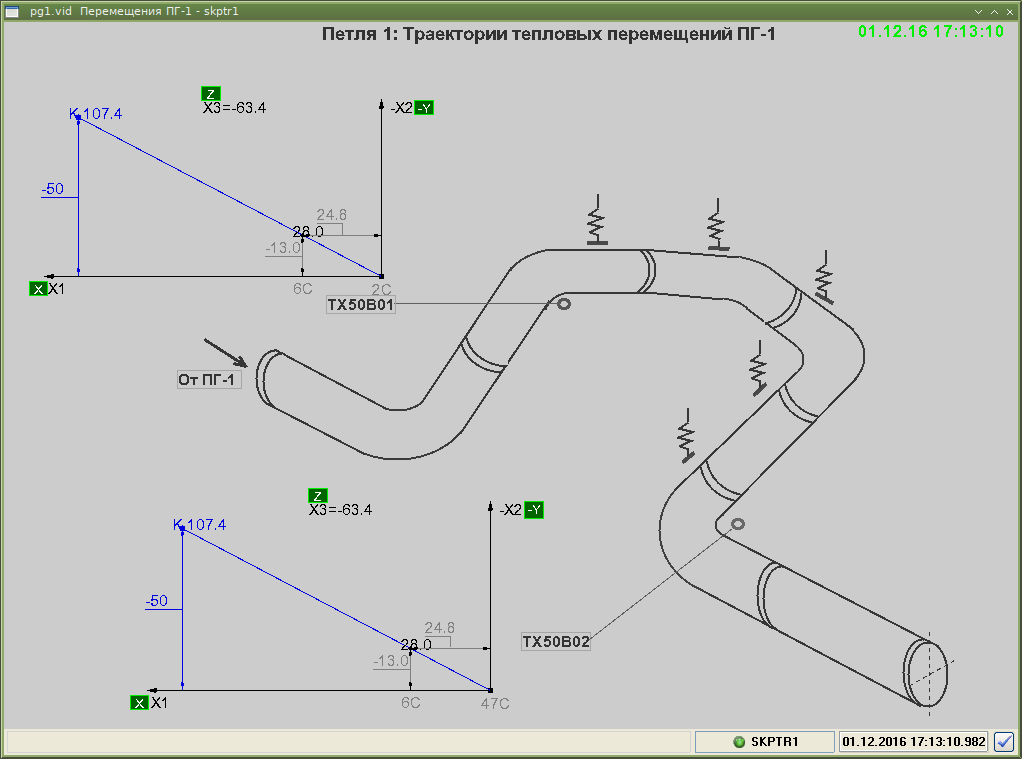

Система контролю переміщення трубопроводів СКПТр

Система призначена для постійних вимірів та фіксації максимальних переміщень трубопроводів в умовах нормальної експлуатації енергоблоку та в перехідних режимах.

Функції СКПТр:

- Прийом та обробка сигналів від датчиків трикоординатного переміщення, прийом технологічних сигналів тиску та температури в парогенераторі;

- Постійний дистанційний контроль переміщення трубопроводів по трьох взаємно перпендикулярних осях та ведення бази даних;

- Надання оператору інформації про переміщення трубопроводів у вигляді відеограм;

- Передача інформації про переміщення та порушення допустимих меж переміщень у суміжні системи;

- Подання інформації персоналу енергоблоку про несправності та збої, формування сигналізації про неприпустимі переміщення трубопроводів.