Accident and post-accident monitoring system

The PAMS accident and post-accident monitoring system is intended for monitoring of safety parameters and state of reactor facility’s systems during design and beyond-design accidents.

PAMS implements functions of accident and post-accident monitoring at any design-relevant initial events, as well as beyond-design accidents (including those connected with severe damage of fuel).

Functions of PAMS:

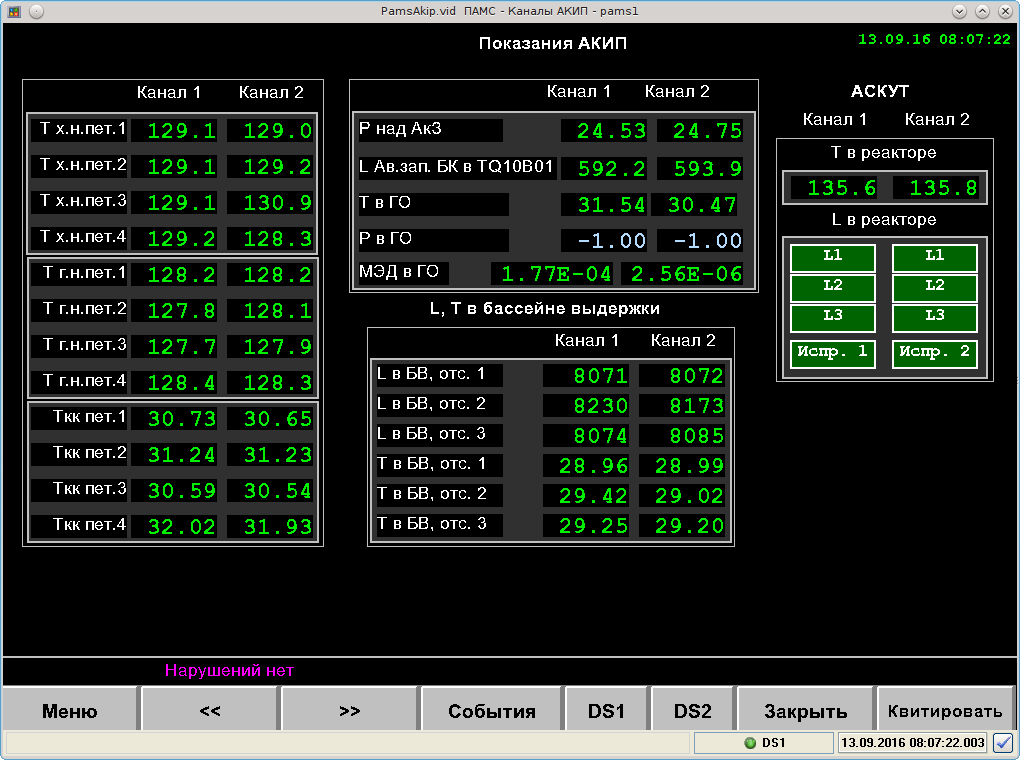

- monitoring the following RF parameters with the use of emergency measuring instrumentation (EMI):

- level of coolant in a reactor;

- level in a cooling pond;

- temperature in a cooling pond;

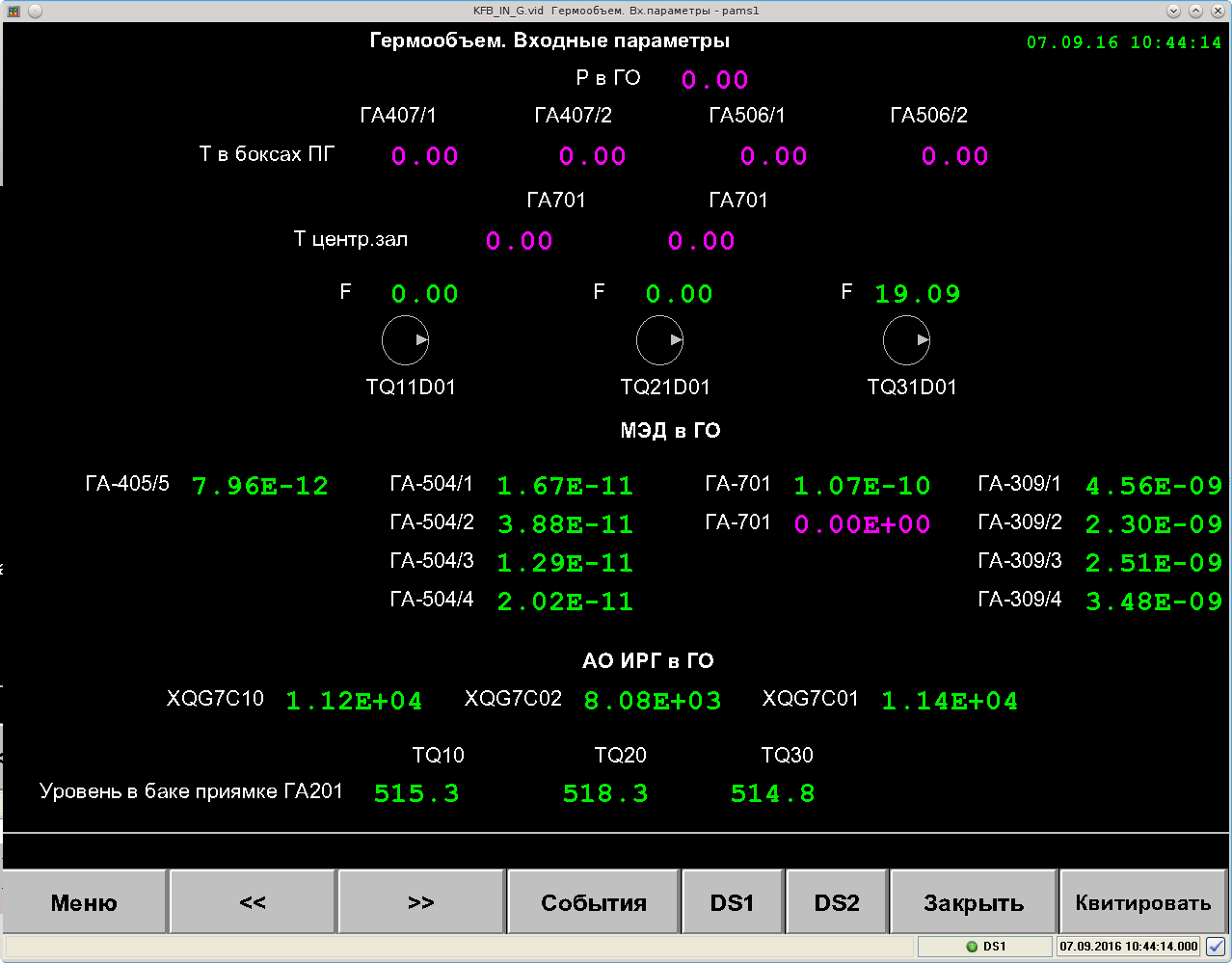

- temperature in a containment;

- containment radiation dose rate;

- pressure above a core;

- pressure in an accident confinement area;

- level in containment sumps;

- providing operating personnel of NPP and emergency work headquarters with information on state of main safety functions and reactor facility’s systems with the help of hardware resistant to emergency conditions, as well as data received from standard systems if they keep their operability;

- providing information on state and efficiency of protective barriers based on direct readings of EMI when standard monitoring systems fail during beyond-design accidents.

System advantages:

High failure tolerance

due to use of a distributed two-level structure with the use of two independent channels of data measuring, processing and displaying;

Use of hardware qualified for conditions of design and beyond-design accidents,

including loss of coolant accidents (LOCA);

Use of AKIP with an advanced measurement

range of monitored technological parameters;

Assurance of PAMS operability

under conditions of a maximum design earthquake and full blackout of a power unit.