Safety control system technological

The system is designed to initiate actuation and control of the power units’ safety systems.

Functions of USBT:

- monitoring technological parameters and identifying initial events by primary processing of input signals and generation of current signals in three mutually redundant MSKU channels;

- generating sequence of protective action commands by “2oo4” logic that are stipulated for a detected initial event (protections of emergency core cooling system (SAOZ), pressurizer’s pulse valves protections (IPK), shut-down cooling, protection of IPK SAOZ, step-by-step diesel generator starting algorithms, etc.);

- generating technological protection and interlock commands by “2oo3”, “2oo2”, “1oo2”, “1oo1” logic (protection and interlock of steam pipe and feeding pipe systems, main steam isolation valve, a technical water system, gas blowers, ventilation systems and conditioning, oil pumps, etc.);

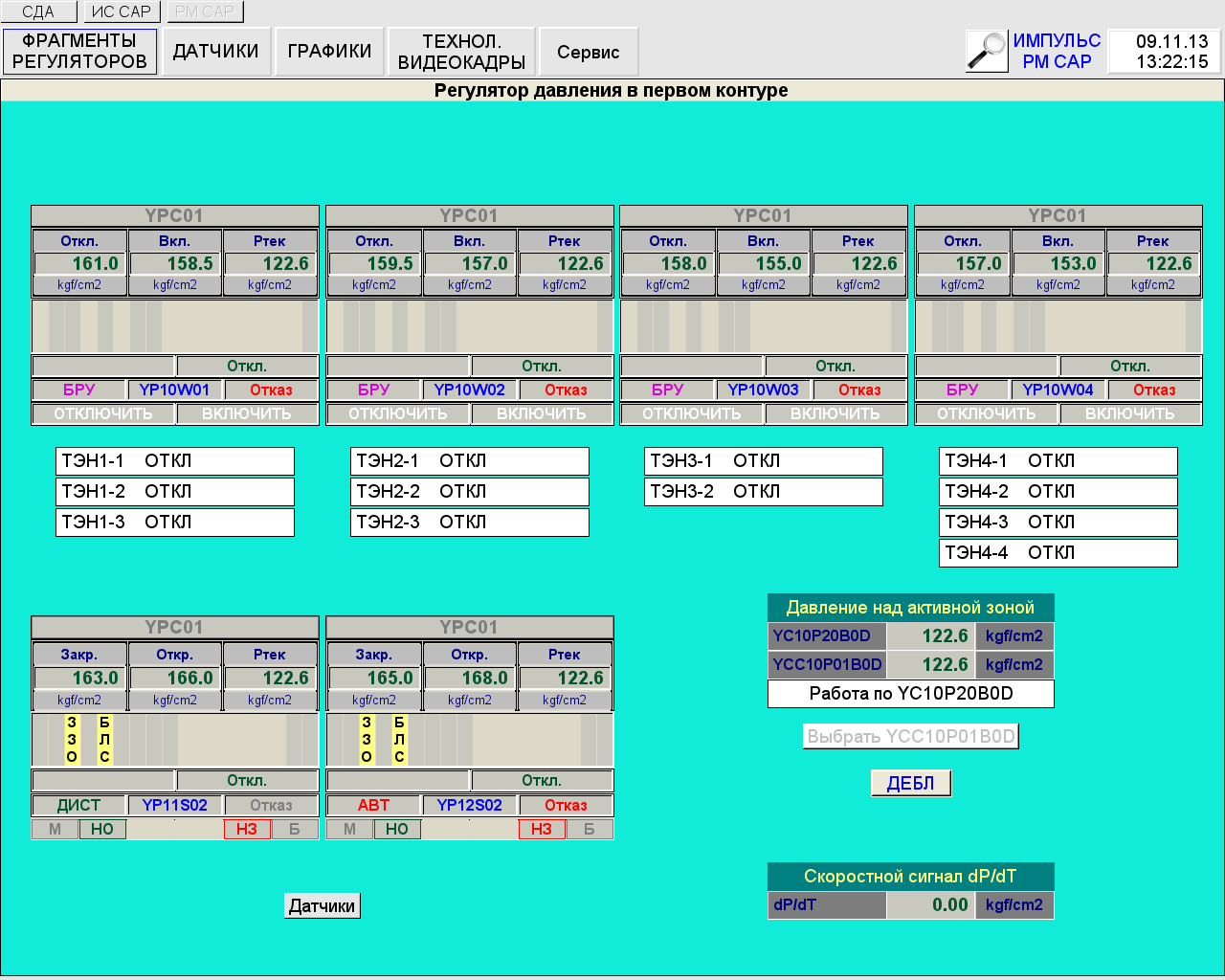

- automatically regulating technological parameters;

- automatically controlling actuators;

- remotely controlling and indicating actuator state in MCR, BCR;

- generating technological and warning alarm signals in MCR, BCR;

- transferring data on technological parameter values, state of protections, interlocks, and actuators, diagnostic data to unit’s IVS;

- visualizing, archiving, and logging current data.

Advantages:

High fail-safety

due to use of redundant hardware;

Ergonomic and intuitively clear operator’s interface;

High level of system’s security

to cyber threats.