Integrated management system

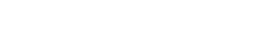

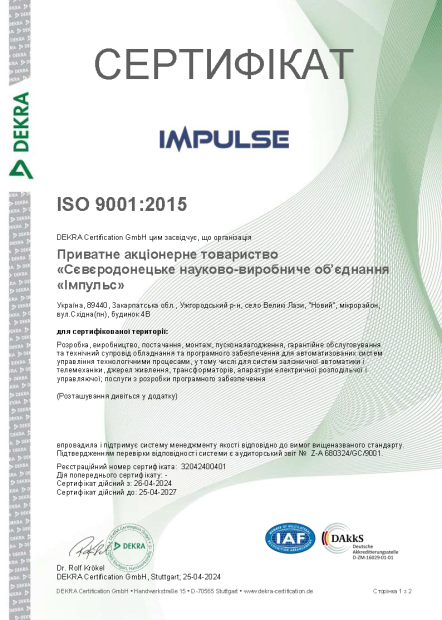

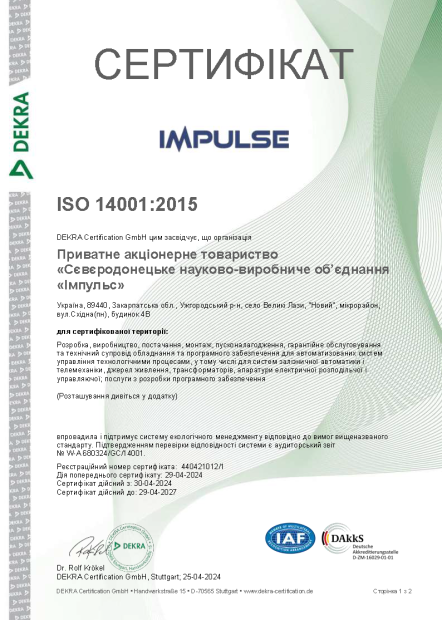

The company’s activities are carried out in accordance with national and international standards: DSTU ISO 9001:2015, ISO 9001:2015, DSTU ISO 19443:2019, and ISO 19443:2018 – quality management system; DSTU ISO 45001:2019 and ISO 45001:2018 – environmental management system, DSTU ISO 14001:2015 and ISO 14001:2015 – occupational health and safety management system.

The most important areas of the company’s policy are the continuous improvement and development of the IMS and ensuring its compliance with the relevant requirements, including:

-

continuous improvement of customer satisfaction;

-

maintaining and strengthening its position as a market leader and manufacturer of high-quality products;

-

development, production, and supply of high-quality competitive products that meet the requirements of Ukrainian national standards, international standards, and the standards of countries to which products are exported;

-

expansion and conquest of new markets through continuous improvement of product quality;

-

obtaining sustainable profits to increase the financial stability of the enterprise and the level of well-being of each employee;

-

reducing the risks and consequences of negative impact on the environment in the course of activities;

-

ensuring that nuclear and radiation safety is taken into account in decision-making and is not compromised by any decisions taken;

-

developing personal responsibility and commitment to a culture of safety among all those whose activities affect the safety of the NPP;

-

minimizing risks and preventing threats of injury and illness among employees;

-

improving working conditions and increasing the safety of employees..

The implementation of the most important areas of the company’s policy is ensured by:

-

the leadership of top management and the heads of each department in activities to improve quality, the constant demonstration of a commitment to improving quality by personal example, and the involvement of personnel in quality management;

-

the formation and development of a culture of safety among employees, strict adherence to documented procedures and job (work) instructions;

-

the application of a process approach and risk-oriented thinking in management decision-making, the continuous collection and analysis of data on actual cases of risk realization, potential threats, and opportunities;

-

continuous improvement of the IMS;

-

allocation of the necessary labor, material, technical, information, and financial resources and control of their rational use to achieve the set goals in the field of quality, ecology, safety, and labor protection;

-

clear distribution of responsibilities and powers between departments and employees;

-

application of modern technologies, new equipment, and modernization of production;

-

quality control of products at all stages of the production cycle, timely implementation of corrective and preventive measures;

-

improvement of the production culture, maintenance of the necessary level of staff competence;

-

elimination of hazards and reduction of risks, including those related to injuries and deterioration of employee health.