|

The ARM-I automatic power controller is designed for automatic regulation of reactor power and main steam collector’s pressure.

Functions of ARM-I:

- automatically regulating RF power and limiting RF power depending on pressure in main steam collectors (GPK);

- automatically regulating pressure in GPKs;

- inputting and archiving values of technological parameters and current data (operation and regulation modes, control and information signals to external systems, technical state of ARM-I equipment, etc.);

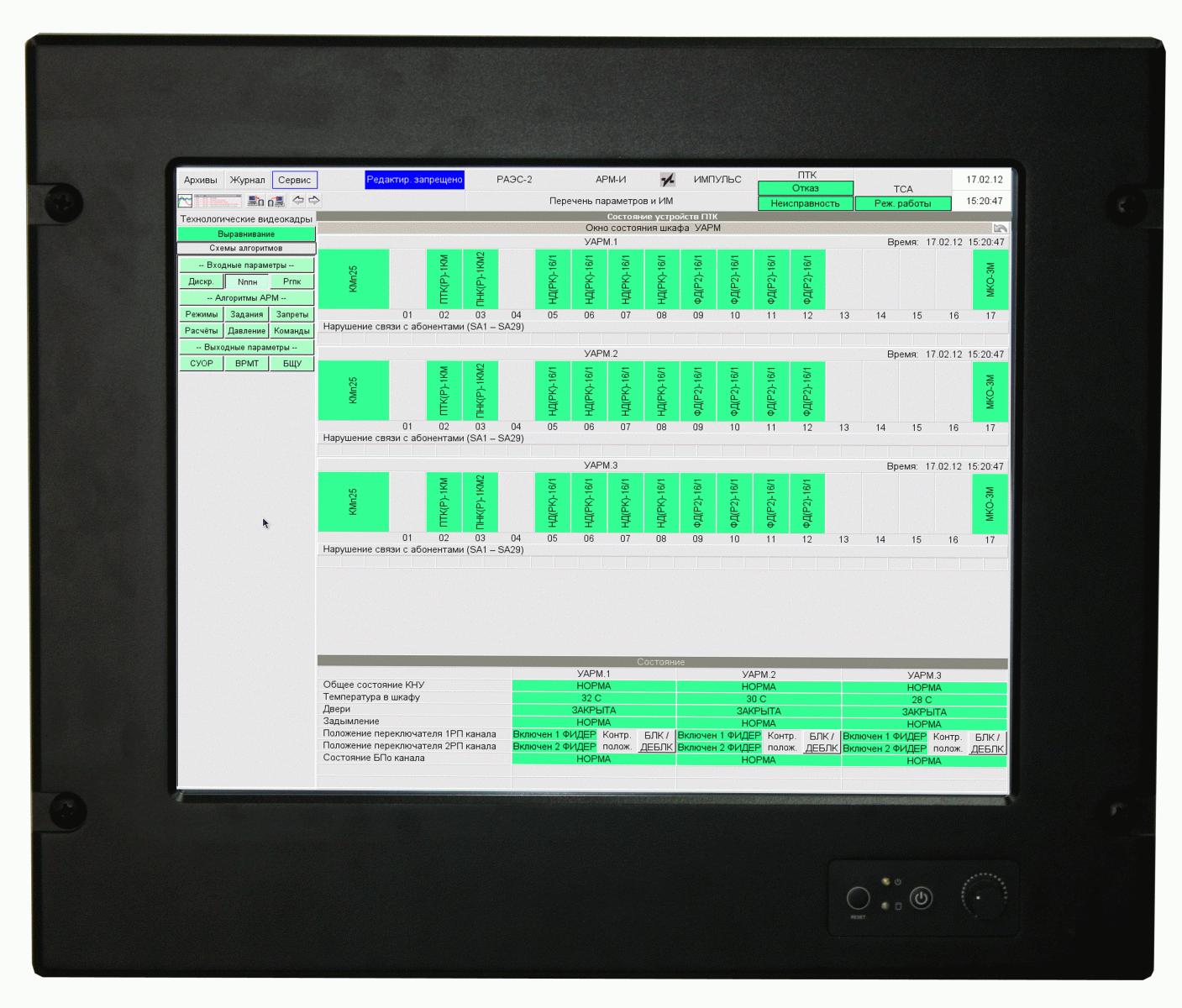

- visualizing technological process data on a display of a registration and visualization device (URO);

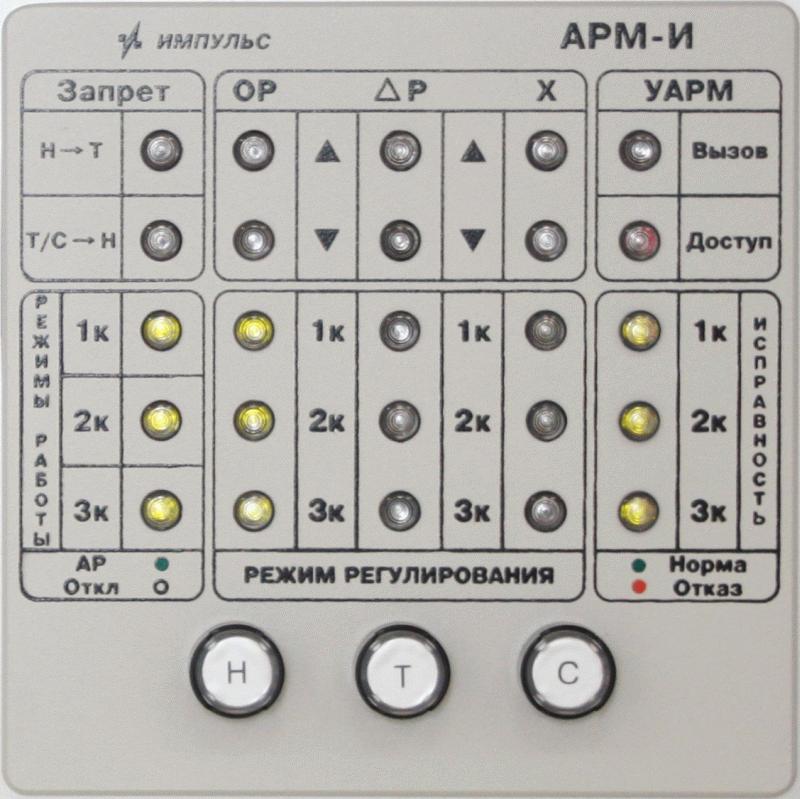

- visually alarming on generation of ARM-I control actions, change of operating conditions, operation and regulation modes, change of a technical state of ARM-I channels;

- displaying parameter trends, state check and ARM-I channel setting reports;

- supporting operator actions during ARM-I channel setting change;

- visualizing current technological and diagnostic data on an ARM-I state in a text, digital, and graphical form on a display of an operating personnel’s workstation.

Composition of ARM-I:

- an automatic regulation subsystem – generates control actions to keep technological parameters in compliance with specified regulation algorithms (consists of three automatic power regulation channels implemented based on industrial controllers of MSKU series);

- a subsystem for communication with an operator – serves for selection of an operation and regulation mode, indication of an ARM-I state (implemented based on a switch of operation mode selection and a switch and indicator unit located in a main control room);

- a technical diagnostic and archiving subsystem – serves for storage, display and archiving of technological and diagnostic information, as well as for change of adjustable ARM-I operation parameters (implemented based on URO built into an automatic power regulation device and a remote workstation);

- a switching subsystem – serves for organization of message exchanges between channels of ARM, URO, and a remote workstation (implemented based on automatic power regulation device’s (UARM) network equipment – a switchboard and a local network converter).

System advantages:

- generation of control actions according to majority principle “2 of 3”;

- possibility of automatic reactor power regulation in three modes – maintaining a set value of neutron flux density, maintaining a set value of pressure in GPK, power limitation depending on pressure in GPK;

- automation of non-operative operability tests and UARM measuring channel calibration.

Safety class – 3.

Safety category – B.

Implementation facilities:

Kola NPP, unit 4 (as a part of KE SUZ)

|

Automatic power regulation device

Registration and visualization device

Switch of operation mode selection

Switch and indicator unit

|