Chapters of history of Severodonetsk RPA “Impulse”

In September 2016, Severodonetsk Research and Production Association “Impulse” (SRPA “Impulse”) was 60. The history of the enterprise is closely connected with the formation and the development of computer machinery for monitoring and control of technological processes. Over these years, hundreds of models of processors, peripheral equipment, industrial controllers, operator equipment, different automation devices, system and application software have been developed and mastered in the batch production.

Based on the developments by RPA “Impulse”, tens of thousands of software and hardware systems (PTK) of instrumentation and control systems have been produced for such industries as: nuclear and thermal power engineering, oil and gas, chemical, aerospace, transport, metallurgy, mechanical engineering, geophysics, defence, marine, etc.

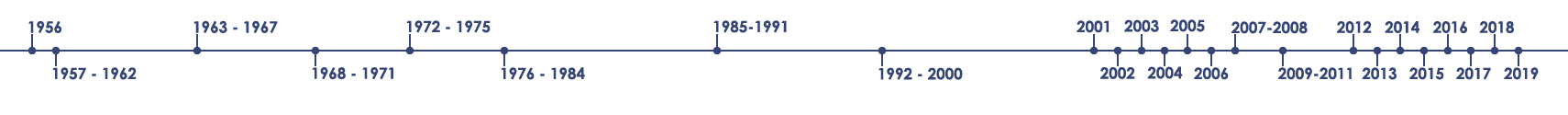

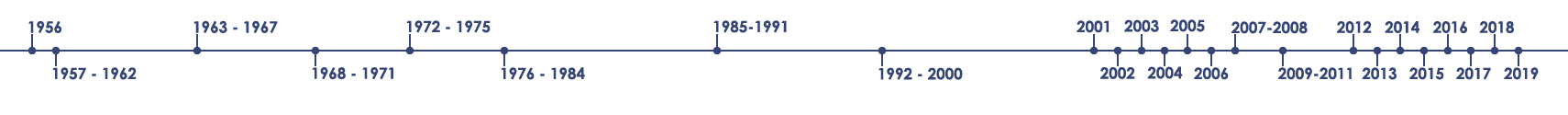

Navigation

1956

Foundation of the enterprise

In 1956, Lisichansk Branch of Moscow Special Design Engineering Bureau No. 245 (SKB-245) – a leading organization for computer machinery in the USSR, was founded in Severodonetsk. Construction of Severodonetsk Instrument Engineering Plant (SPZ) started, which completed in 1960. Personnel of Lisichansk Branch of SKB-245 almost completely consisted of young specialists – graduates of universities of Moscow, Leningrad, Kyiv, Kharkiv, Lviv, Taganrog, Odessa, Penza, etc.

Viacheslav Tolkachev – a young Candidate of Technical Sciences, was appointed as Head of Lisichansk Branch of SKB-245. In 1958, Lisichansk Branch of SKB-245 became subordinated to Kyiv Automation Institute as its branch (LFIA).

1957-1962

Creation of specialized computer complexes for specific customers (“Adviser of a blast furnace master” for “Azovstal” Plant, Dnipropetrovsk, Kryvyi Rih Iron and Steel Works; “Automatic operator” for Chernorechensk Chemical Plant; “Automatic dispatching system” for Severodonetsk PA “Azot”).

Details »

In 1959 , Andrii Novokhatnii became Director of Lisichansk Automation Institute. In 1963, the branch was reorganized into Research Institute for Control Computers (NIIUVM) of the Instrumentation Ministry of the USSR, Andrii Novokhatnii was appointed as its Director.

Creation of specialized computer complexes for specific customers (“Adviser of a blast furnace master” for “Azovstal” Plant, Dnipropetrovsk, Kryvyi Rih Iron and Steel Works; “Automatic operator” for Chernorechensk Chemical Plant; “Automatic dispatching system” for Severodonetsk PA “Azot”).

“Automatic operator” machine

Functions of the “Automatic operator”: direct digital PID control of the nitric acid concentrating with the Т period (3-5 min); recording of the main parameters and warning on the violations of the technological process.

The computer controlled information complex consisted of four functional parts.

- An input device or a device for a communication with a facility assuring information acquisition from a control facility, conversion of received analogue signals into a digital form, input of digital information into the machine. Serial devices with a unified input served as sensors of measured parameters. Accuracy of conversion - 8 binary digits. The input device assured communication of the processor with a controlled facility, inquiring sensors in cycles.

- The processor part of the machine was built on ferrite-diode logical elements. The processor performed 28 arithmetic, logical and control operations. Performance - 900 additions, 80 multiplications, 70 divisions per a second. A random access memory on ferrite cores with the diameter of 1 mm, size of 256 18-digit binary words.

- To store control programs, constants and setpoints, a read only memory on ferrite cores with the diameter of 4 mm was used. Information was entered into it by means of weaving of ferrite rings. To set a variable part of a setpoint, there was a patch board switched with patchplugs.

- An output device for conversion of calculated digital control actions into proportional pneumatic signals from 0 tо 1 atmosphere with the accuracy of 7 binary digits. The signals were transmitted to pneumatic actuators (pneumatic valves), which assured control of the technological process. Also, it shaped discrete signals.

“Automatic dispatching system”

Functions of the “Automatic dispatching system”: monitoring of operation of the ammonia and alcohol production; logical analysis of the violations of the technological processes; automatic control of the composition of the synthetic gas аnd the blowdown gas in the ammonia production; automatic record keeping of the supply streams and calculation of the technical-economic indicators of each shop and the production in whole. A device for a communication with a facility was a combined telemechanical subsystem allowing measuring 360 instantaneous values of the parameters, 120 integral values of the parameters, 360 two-position signals with the cycle of 20 sec, 200 instantaneous two-position signals. The system generated 200 single-position commands, 24 analogue control signals 0-5 mA. Information was acquired via radial channels through 10 group check points installed in the shops, which acquired information from primary transducers. Group transducers were radially connected to the computing machine. The distance from the machine to the group transducers was allowed up to 1.2 km. The information acquisition cycle was 60 sec.

The computing part of the “Automatic dispatching system” was built on ferrite-diode logical elements, had a ferrite memory on 1860 twenty-digit numbers, a ferrite passive memory with the size of 5632 twenty-digit numbers. The arithmetic device operated 18 digit numbers with a fixed point. The command system was single address, the quantity of operations was 28. The operation was carried out according to a fixed program written in machine instructions.

Remark: Trial operation started since 1965, the system was introduced into round-the-clock operation at the chemical plant in 1967 and was operating for 24 years.

“Automatic dispatching system”

« Hide

In 1959, Andrii Novokhatnii became Director of Lisichansk Automation Institute. In 1963, the branch was reorganized into Research Institute for Control Computers (NIIUVM) of the Instrumentation Ministry of the USSR, Andrii Novokhatnii was appointed as its Director.

1963-1967

Development and manufacturing of MPPI-1, UM-1, KVM-1, “Angara”, “Baikal” control computers. The control system for the sorting complex based on 18 “Angara” machines and a “Baikal” machine was put into commercial operation at Bratsk Timber Processing Complex.

Details »

Development and manufacturing of MPPI-1, UM-1, KVM-1, “Angara”, “Baikal” control computers. The control system for the sorting complex based on 18 “Angara” machines and a “Baikal” machine was put into commercial operation at Bratsk Timber Processing Complex.

MPPI-1 machine

A primary information processing machine (MPPI) was designated for acquisition, normalization and primary processing of information, output and recording of instantaneous and calculated values of the parameters of the controlled process, as well as tendencies of their change to local operating personnel. It performed a function of an industrial controller.

MPPI-1

UM-1 machine

UM-1 second-level control machine.

It included the following: a computing part and USO devices for communication with a facility.

The computing part of the UM-1 machine was built on ferrite-diode elements, had ferrite random-access and read-only memories (correspondingly 1024 words х 4 and 2048 words х 3), performed 30 arithmetic and logical operations on 21 digit binary numbers with a fixed point with the speed of 900 oper/sec. A distinguishing feature of the machine was availability of an interrupt system assuring execution of 16 different, not interconnected programs with the automatic selection of the most important and difficult inquiry by the given priority.

The USO of the UM-1 machine could receive up to 352 analogue current signals; signals of thermocouples and thermistors up to 256; signals from air sensors up to 256; position signal up to 600; up to 60 number-impulse signals. At the output, the USO has up to 10 electric signals; up to 128 analogue pneumatic ones, up to 400 position electric signals.

Besides the functional tasks, the dialogue of an operator and the machine and the operating testing and diagnostic procedure were implemented in the multiprogram mode.

UM-1

KVM-1 machine

A KVM-1 coordinating machine interacting in the real time with 65 users of the UM-1 and MPPI-1 type at the distance up to 12 km, connected with the KVM-1 with radial communication channels.

Also, the KVM-1 could operate with own devices for communication with a facility when solving control tasks requiring large computation capacities.

The KVM-1 computer complex could perform 256 different operations with the speed of 100 thousand operations per a second. Operations were performed both with the fixed point and with the floating one on 25 and 50 digit words. The machine had a modular main memory up to 126976 words in modules by 4096, a long-term magnetic-tape memory with the capacity of 20 million words. The multiprogramming system responding to 80 asynchronous inquiries allowed creating a real-time operating system including diagnostic facilities. Compilers for several subsets of the ALGOL-60 language were developed for the KVM-1. The machine was equipped with a console for interaction of an operator with the process in the dialogue mode with the two-colour printing of the dialogue text. The interesting peculiarity of the KVM-1 was the fact that a special set of logical elements on tunnel diodes and transistors was developed for it, which allowed achieving high performance of the machine.

KVM-1

« Hide

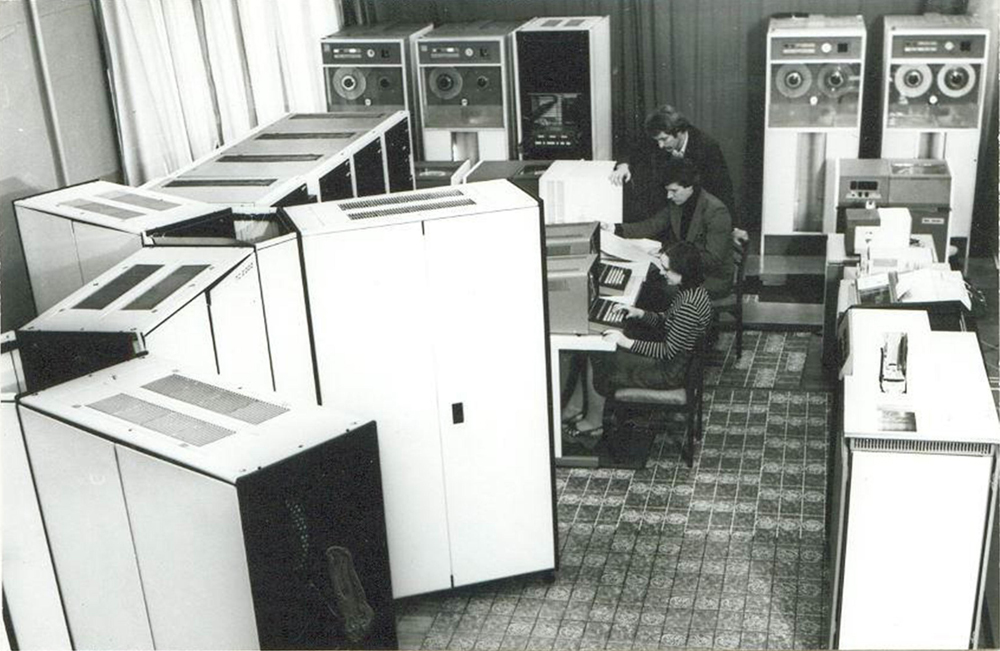

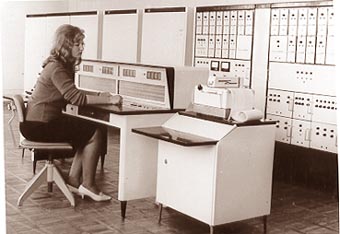

1968-1971

Creation of М-2000, М-3000 computing machines – the first in the USSR computers with the third-generation architecture (IBM/360). Development and commissioning of the first in the USSR Sirena-1 automated flight ticket selling network (based on an М-3000 third-generation computer), which assured ticket selling for flights from airports of Moscow.

Details »

Creation of М-2000, М-3000 computing machines – the first in the USSR computers with the third-generation architecture (IBM/360). Development and commissioning of the first in the USSR Sirena-1 automated flight ticket selling network (based on an М-3000 third-generation computer), which assured ticket selling for flights from airports of Moscow.

The М-2000 and the М-3000 had the structure and the architecture of the IBM/360 system. Herewith all machines were equipped with the range of peripheral devices, among which were devices for communication with a facility.

The console of a process operator assured output of information: warning on the state of the facility’s equipment, indication of recommendations in the alphanumeric form, as well as input of digital data, output of the parameters for digital indication, output of the parameters for printing.

All devices of the computer systems were structurally made based on standard cabinets, where units of elements and power supply units of the cassette design were placed.

M-3000

The first area of application of the М-2000, М-3000 computer complexes became not process facilities, but a “Sirena” reservation system for the airlines of Aeroflot.

“SIRENA-1” computer network

“Sirena” is a global system for mass service including hundreds of terminal stations (workstations of cashiers), tens of message processing and switching centers.

The “Sirena” system included the following:

- a computer complex for the Moscow Reservation Center;

- means for communication with users via standard, then poorly developed and low-quality channels for transmission of digital information;

- a large archive fast memory with the assurance of the information integrity in the emergency modes;

- means for dialogue communication of the system with a user – consoles of cashiers to shape requests from clients and to give a ticket, a reference, mass information to an indicator panel, an individual reference, etc.

- a system of software meant for reliable functioning of the system for the benefit of a client and Aeroflot in whole.

In the computer center of the “Sirena” system, an М-3000 complex was installed. The complex assured selling of up to seven tickets per a second.

Telephone and telegraph dedicated and switched channels of city automatic telephone systems were used as the main communication channels. All communication channels were connected to the system by means of specially developed data transmission equipment assuring transmission of digital information at the speeds of 600 or 1200 bauds.

For the center of inquiry acquisition by 256 communication channels and data exchange with the local computer centers, communication modules were used, each of which assured communication by 32 telephone dedicated channels, 32 telegraph switched or dedicated channels of city telephone systems. The extensive two-way network connected the center with the terminals at the distance of up to 8 thousand km with the speed of 600-1200 bauds. Users of the network - telegraphs, consoles of cashiers and regional information processing centers, later based on М-6000 и М-7000 computers. The computer complex included a magnetic drum with the high-capacity memory. The console of a cashier organized as a video terminal allowed a passenger-cashier-system dialogue when shaping an inquiry and preparing a ticket.

Sirena-1 in the building of the Moscow Aviation Node

« Hide

1972-1975

Development and start of the batch manufacturing of М-6000, М-7000 control computers for such branches of: thermal power engineering, oil and gas, chemical, aerospace, metallurgy, mechanical engineering, defence, marine, etc.

Details »

Development and start of the batch manufacturing of М-6000, М-7000 control computers for such branches of: thermal power engineering, oil and gas, chemical, aerospace, metallurgy, mechanical engineering, defence, marine, etc.

М-6000 control computer

The prototype of the М-6000 was a minicomputer “Parametr” developed by 1972, which had means for communication with facilities and software oriented to control tasks.

Parametr

The М-6000 was one of the first machines forming a part of the modular system of computer aids (АSVТ-М). The М-6000-type hardware set was a set of aggregate modules executed on elements of microelectronic technique and allowed composing software and hardware systems of instrumentation and control systems by the design-basis way.

The М-6000 had the following:

- extensive input-output system;

- friendly system for priority interruption allowing combining input-output operations with calculating;

- high performance for that time (up to 2 000 000 address operations and up to 1 800 000 no-address micro-operations per a second);

- main memory up to 65 736 bytes;

- possibility to connect fast-acting channels for direct access to the memory, executing input-output operations without interruptions of the processor.

Software of the М-6000, from the composition of the modular system of software (АSPО), controlled the system for information acquisition, its processing and the dialogue with a process operator.

М-6000

М-7000 control computer

A dual-processor central computer was in the М-7000.

High reliability of such software and hardware systems allowed using them for direct control even of such important facilities as nuclear power units.

М-7000

« Hide

1976-1984

Since 1976, supplies of digital control complexes to nuclear power plants started. The first complexes based on the М-7000 redundant control machines were commissioned at Beloiarsk, Novovoronezh, Rivne NPPs.

In 1976, works started under the international program for creation of a series of small control computers.

Remark: Before 1990, more than 10 000 of SМ-1, SМ-2, SМ-2М, SМ-1210, SМ-1634, TVSО-1, PS 1001 complexes were produced according to developments by SRPA “Impulse” at several production facilities.

Details »

Since 1976, supplies of digital control complexes to nuclear power plants started. The first complexes based on the М-7000 redundant control machines were commissioned at Beloiarsk, Novovoronezh, Rivne NPPs.

In 1976, works started under the international program for creation of a series of small control computers.

Remark: Before 1990, more than 10 000 of SМ-1, SМ-2, SМ-2М, SМ-1210, SМ-1634, TVSО-1, PS 1001 complexes were produced according to developments by SRPA “Impulse” at several production facilities.

Series of the SМ-1, SМ-2, SМ-1210 UVKs (control computer complexes) of a class of 16-bit minicomputers

Models of this series had software compatibility with the М-6000 and the М-7000. Processors of the SМ-1 and the SМ-2 were built using a microprogram control principle. The SМ-1 and SМ-2 complexes were composed by a manufacturing plant according to the customer’s specification based on processors and aggregate modules from the computer SM nomenclature. Software of the SM 1 and SМ 2 UVKs was built according to a modular principle. The software included:

- a multitask multiprocessor operating system;

- subprogram libraries;

- a task-oriented macrodefinition packet allowing an I&C designer to compose software systems to acquire, analyze and process technological information;

- a system to prepare application mnemocode (assembler), macrolanguage, Fortran-II, Fortran-IV, ALGOL-60 and BASIC programs.

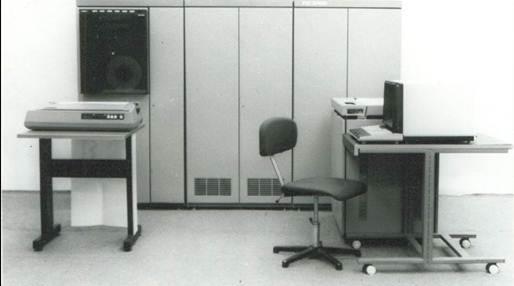

SМ-1

SМ-2М

SМ-1210

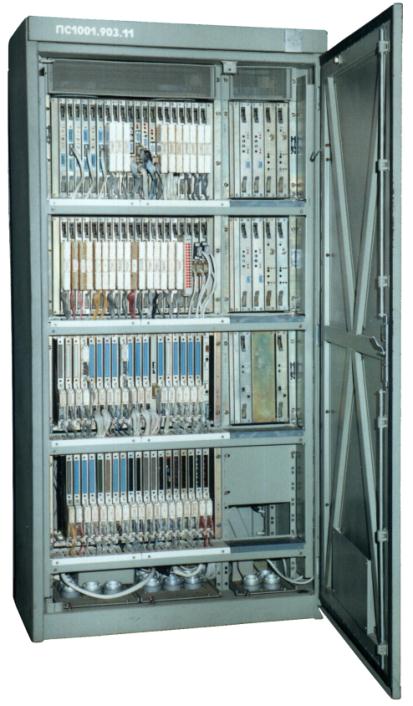

PS-1001 control computer complex

A super-reliable PS 1001 control computer complex was used to automate critical national-economic facilities. A “2 of 3” majority redundancy principle with the sliding recovery of failed components was used in the complex.

The PS-1001 UVK was developed to replace the SМ-2М, SM-1634, SМ-1210 UVKs and the SSO-1, SSО-2, TVSО-7, RMOT-02 terminals form communication with a facility.

To increase effectiveness, several functions of the operating system were implemented firmware-based in the PS-1001 UVK.

The software of the PS-1001 UVK implemented based on an ASPO included the following: packets of software units to compose different types of operating systems (single-machine and multimachine, real-time and time-sharing); a system to prepare programs and micriprograms; task-oriented packets and program libraries.

PS-1001

The system to prepare programs of PS-1001 included the following: a system for programming on the following languages: Mnemocode; Macrolanguage; Fortran; BASIC-РВ (with the support of the real-time mode); COBOL; Pascal, etc. The task-oriented software included the following: a packet of software units for I&C systems; a packet of software units to arrange databases; libraries of application programs.

Remark:In 1987, the Institute of Control Issues of Academy of Sciences of the USSR developed a design of a unified I&C system for WWER-type power units based on the PS 1001 manufactured by SRPA “Impulse”.

« Hide

In 1980, an I&C system for sporting events based on the М-7000 two-processor machines was commissioned within an “Olimpiada-80” I&C system.

Details »

In 1980, an I&C system for sporting events based on the М-7000 two-processor machines was commissioned within an “Olimpiada-80” I&C system.

The “Olimpiada” I&C system was a complex of three systems: an “Organizing Committee” I&C system, an I&C system for sporting events and an “Information” I&C system.

The I&C system for sporting events operated based on three regional information computer centers (RIVTs) in Moscow and one in the Yachting Sport Center in Tallinn. Each of them had two М-7000 ASVT dual-processor computers with the capacity 200000 operations per second each. The external memory – magnetic disk memory with the capacity 30 million symbols. Sports facilities had video terminals to input and output information with printing devices. The quantity of the terminals at RIVTs “Luzhniki” - 23, at RIVTs “TsSKA” - 14, at RIVTs at the firing range — 6 and at RIVTs “Tallinn” - 17.

« Hide

1981. Start of series production of PS-2000, PS-3000 high-performance multiple-processor computers. They found usage not only in geophysics, but also in systems processing hydroacoustics data, images (received during space sounding of the Earth), telemetric data received from space objects, scientific experiments, as well as in defense industry.

Details »

1981. Start of series production of PS-2000, PS-3000 high-performance multiple-processor computers. They found usage not only in geophysics, but also in systems processing hydroacoustics data, images (received during space sounding of the Earth), telemetric data received from space objects, scientific experiments, as well as in defense industry.

PS-2000 computer

Architecture of the PS-2000 – SIMD-type (single instruction, multiple data — single instruction stream, multiple data stream, OKMD).

Performance of the PS-2000 - 200 million operations per sec. It had up to 64 processor elements, the structure of interaction of which in the process of calculations was determined by algorithms of tasks.

Remark: An article was published in the journal “Control Devices and Systems” 1992, No. 10 “Assessment of performance of PS2100 computers”.

Download...

The following model PS-2100 (developed in 1988) reached performance of 1,5 milliard operations per sec. These parameters were reached due to implementation of processor elements on master chips (BMK) manufactured according to the KMOP (complementary metal oxide semiconductor)-technology at RPA “Elektronika”, Voronezh.

PS 2100

PS-3000 computer

PS-3000 computers belong to computer systems with the MIMD architecture (Multiple Instruction stream, Multiple Data stream, MKMD in brief). Composition of the PS-3000: 4 central (scalar) processors (SP); 2 homogeneous decision fields (vector processors - VP), each of which is accessible for two SPs and consists of eight single-type, autonomously and asynchronously operating processor elements (PE); 4 modules of common parallel random-access memory (4 MB in each); up to 16 system subcomplexes (peripheral processors - PP). All TsPs and PPs have direct access to all random-access memory. All processors and decision fields of the PS-3000 MVK (multicomputer system) can operate simultaneously and asynchronously with each other.

Up to eight instructions can be in the SP simultaneously at different processing stages. Besides traditional instruction and address processing functions, the SP provides the following:

- execution of scalar instructions of the given program;

- transmission of vector instructions and data into VPs and receipt of results;

- processing of interruption of the given program;

- execution of a part of functions of the operating system (using hardware and microprogram support) as to switching of tasks and their branches.

The software of the PS-3000 MVK includes one of versions of the Unix operating system, tools of programming on the Macro Assembler, Pascal, Fortran-77, C languages, libraries and packets of application programs.

« Hide

1982. The order of the Instrument Engineering Ministry of the USSR appointed RPA “Impulse” the Leading Organization for Creation, Commercial Development and Introduction of Control Computer Machinery for Nuclear Power Engineering.

1984. The first person who had a spacewalk, a pilot cosmonaut of the USSR, the Deputy Head of the Cosmonauts' Training Centre Oleksii Leonov paid SRPA “Impulse” a working visit. Developments of the enterprise and the plant were shown to Oleksii Leonov and his accompanying persons. The result of the visit was a contract for supply of computer equipment and software for the Cosmonauts' Training Centre.

1985-1991

The SМ-2М redundant control complexes were commissioned at 22 power units of the East European countries.

1986. Basic components of an MSKU М Microprocessor Instrumentation and Control System were developed. The MSKU is directed toward creation of fail-safe control systems with the distributed structure. Remark:It was upgraded till 2000.

Details »

1986. Basic components of an MSKU М Microprocessor Instrumentation and Control System were developed. The MSKU is directed toward creation of fail-safe control systems with the distributed structure. Remark:It was upgraded till 2000.

MSKU M microprocessor instrumentation and control system

МSKU М was built according to the principle of the distributed decentralized microprocessor instrumentation and control system.

The nomenclature of MSKU М products allowed creating by way of design software and hardware systems for instrumentation and control systems with the required configuration and reliability.

Creation of the PTK’s software was limited to the process of arrangement and adjustment of standard software from the composition of an all-purpose library of software units. PTKs based on the МSKU М assured implementation of the whole range of control systems - from single-circuit regulation to adaptive control of complicated technological processes.

Both special industrial local area networks (LAN) and all-purpose LANs of the Ethernet, Arcnet type served for high-speed information exchange between components. An MAPS modular asynchronous reconfigurable network was used as a special LAN in the MSKU.

MSKU industrial controller

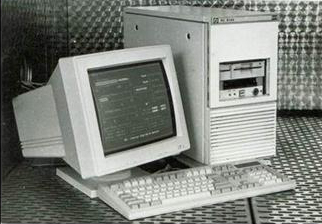

PS 5100 industrial computer

PS 5300 workstation

« Hide

1992-2000

Tens of instrumentation and control system were commissioned on the MSKU М platform. The main ones are as follows:

- in the nuclear power engineering: Kola NPP, power units 1, 2 – process information system; Kursk NPP – I&C system of open distribution devices 750kV; Zaporizhzhia NPP, power unit 3 – ICMS-М in-core monitoring system; PA “Maiak” (Oziorsk of Cheliabinsk region) – “Ruslan” and “Liudmila” reactor facility control system;

- in the thermal power engineering: I&C systems for power units with 800, 300, 200 MW at Zaporizhzhia, Vuhlehirsk, Kurakhove, Kirishi, Zmiiiv, Beriozovskaia thermal power plants;

- in the oil and gas industry: I&C systems of gas compressor stations at companies “Ukrgasvydobuvannya”, “Ukrnafta”, “Poltavahazprom”, “Donbastranshaz”.

Scientific-technical articles were published in different editions.

Details »

Scientific-technical articles were published in different editions.

An article was published in the journal “Control Devices and Systems” 1994, No. 06 “Experience of implementation of a process information system for technological monitoring at power unit 2 with the WWER-440 reactor of Kola NPP”.

Download...

An article was published in the journal “Control Devices and Systems” 1994, No. 09 “MSKU M microprocessor instrumentation and control system”.

Download...

A booklet “Microprocessor instrumentation and control systems at industrial facilities” was published. It described experience of application of the MSKU М at facilities of thermal and nuclear power engineering, metallurgy, oil and gas processing industry, etc.

Download...

An article was published in the journal “Control Devices and Systems” 1995, No. 04 “Software of the MSKU M system”.

Download...

An article was published in the journal “Control Devices and Systems” 1996, No. 04 “40 years in the I&C sphere”.

Download...

Articles were published in the journal “Control Devices and Systems” 1996, No. 10:

- “Prospects of development of the MSKU M microprocessor instrumentation and control system” Download...

- “I&C systems for power units of thermal and nuclear power plants based on MSKU М facilities” Download...

- “Creation and application of computer means to control technological processes in CIS countries”. Download....

An article was published in the journal “Control Devices and Systems” 1997, No. 06 “Process information system of open distribution devices” and “Instrumentation and control system for heating furnaces of the petroleum plant at the Kremenchug refinery”.

Download...

An article was published in the journal “Control Devices and Systems” 1997, No. 07 “I&C system for sugar factories based on MSKU М complexes”.

Download...

An article was published in the journal “Control Devices and Systems” 1998, No. 02 “PS 5101 workstations”.

Download...

An article was published in the journal “Industrial I&C Systems and Controllers” 1999, No. 06 “Instrumentation and control systems based on the MSKU М for thermal and nuclear power engineering facilities”.

Download...

An article was published in the journal “Industrial I&C Systems and Controllers” 1999, No. 09 “МSKU М complex at oil and gas facilities”.

Download...

An article was published in the journal “Industrial I&C Systems and Controllers” 1999, No. 09 “МSKU М complex at oil and gas facilities”.

Download...

An article was published in the journal “Industrial I&C Systems and Controllers” 2000, No. 07 “New generation of MSKU М facilities”.

Download...

« Hide

2001

A second-generation platform - MSKU 2М was developed: MSKU 2 industrial controllers, PS5110, PS5120 workstations, automated workstations for process operators and other equipment. The development started in 1998.

Hundreds of I&C systems were commissioned on the MSKU 2М platform at NPPs of Ukraine and Russia. The main ones are as follows:

- Process information systems, Unit’s upper level,

- ICMS-М in-core monitoring systems,

- AKNP-I neutron flux monitoring systems,

- Safety control systems (on unconditional logic);

- Normal operation systems for the power unit’s reactor facility (on unconditional logic).

Details »

A second-generation platform - MSKU 2М was developed: MSKU 2 industrial controllers, PS5110, PS5120 workstations, automated workstations for process operators and other equipment. The development started in 1998.

Hundreds of I&C systems were commissioned on the MSKU 2М platform at NPPs of Ukraine and Russia. The main ones are as follows:

- Process information systems, Unit’s upper level,

- ICMS-М in-core monitoring systems,

- AKNP-I neutron flux monitoring systems,

- Safety control systems (on unconditional logic);

- Normal operation systems for the power unit’s reactor facility (on unconditional logic).

МSKU 2М

The newest for that time achievements as to the following were implemented in the MSKU 2M Microprocessor Instrumentation and Control System:

- technology of production of industrial computers and controllers;

- industrial design;

- sphere of information technologies;

- structure and architecture of software and hardware systems for I&C systems.

The nomenclature of MSKU 2М products allowed creating software and hardware systems (PTK) for I&C systems in different branches of industry.

The main components of the MSKU 2М:

- communication facilities – industrial and all-purpose LANs;

- PTK’s upper level - PS5110, PS5120 workstations;

- PTK’s lower level – MSKU 2 second-generation microprocessor control computer complexes;

- software.

Main differences of the MSKU 2М system and the MSKU М system:

- MSKUs based on I486, Pentium and better processors;

- workstations based on Pentium III and better processors;

- software both on the OS 5000 platform and on the platforms of the Linux, Windows operating systems.

Functions and structure of the software of the MSKU 2М (SW of MSKU 2М) are oriented to the methods of designing and programming of tasks to control technological processes, where not only facilities for acquisition and processing of information from I&C system’s objects, but also software complexes for information display, for interaction between network abonents, for program preparation and debugging, for measuring and testing procedures, etc. are used.

SW of MSKU 2М includes the following:

- system SW of MSKU 2;

- programming tools of MSKU 2 on the Windows platform;

- system SW of operator and workstations.

MSKU 2 industrial controller

Based on the МSKU 2М, the following was manufactured and commissioned at NPPs of Ukraine (within the Complex Modernization and Safety Upgrade Program of Power Units of Ukrainian NPPs and the Modernization and Safety Upgrade Program of Power Units 2 of KhNPP, 4 of RNPP) and Russia:

- Process information systems (manufactured from 2002 till 2012);

- In-core monitoring systems (from 2002 till 2012);

- Neutron flux monitoring systems (from 2002 till 2005);

- Safety control systems and Power unit control systems based on a UKTS-VL unified hardware complex (from 2002 till 2016);

- UKTS-VL monitoring and diagnostics systems (from 2002 till 2016).

Remark: Details are in the catalog “Highly-reliable instrumentation and control systems for technological processes for nuclear power engineering and other branches of industry”. 2004. Download...

PS 5120 workstation

« Hide

In February 2001, the meeting of the coordination and expert council for NPP I&C systems under NNEGC “Energoatom” took place at the site of SRPA “Impulse”..

Plans for reconstruction of I&C systems of Ukrainian NPPs, in particular plans for creation of new samples of ICMS and IVS were discussed.

The members of the coordination and expert council saw new production facilities of SRPA “Impulse”.

2002

In March 2002, the meeting of the coordination and expert council for NPP I&C systems under NNEGC “Energoatom” was held at the site of SRPA “Impulse”. The members of the coordination and expert council saw the latest developments: МSKU 2, PS 5110, UKTS-VL cabinets, IА-3, IА-4 smooth start-up devices, etc. Reports-presentations were made as to IVS and ICMS-М implemented based on the МSKU 2М.

A booklet “Automatic control system for gas-compressor units (SAU HPA)” 2002 was published.

Download...

An article was published in the journal “Industrial I&C Systems and Controllers” 2002, No. 03 “MSKU 2M microprocessor instrumentation and control system”.

Download...

2003

In May 2003, President of the Ukrainian Union of Industrialists and Entrepreneurs Anatolii Kinakh visited SRPA “Impulse”.

Main directions of works to create PTKs for I&C systems for different branches of industry, and primarily for nuclear power engineering facilities were shown to him, he visited main subdivisions of “Impulse”: laboratories, testing ground, productions areas.

In August 2003, SRPA “Impulse” obtained a license from the State Nuclear Regulatory Committee of Ukraine to design nuclear facilities as to design works for NPP I&C systems and author’s supervision of their operation.

A tutorial “Software and hardware systems for I&C systems” was published, where peculiarities of software and hardware systems (PTK) used for creation of instrumentation and control systems were considered.

Download...

2004

In July 2004, the meeting of the coordination and expert council for NPP I&C systems was held at the site of SRPA “Impulse”.

The issues relating to development and implementation of complexes of I&C systems at power units of Ukraine were considered. The members of the coordination and expert council saw the plant of CJSC “SRPA “Impulse”, technology of hardware manufacturing and adjustment.

A catalog “Highly-reliable instrumentation and control systems for technological processes for nuclear power engineering and other branches of industry” was published. It included descriptions of components of the МSKU 2М and systems based on them.

Download...

2005

The third-generation platform - МSKU 3М was developed: industrial controllers, workstations, equipment for arrangement of reactor control and protection systems and other equipment. Remark: The development started in 2003.

Details »

The third-generation platform - МSKU 3М was developed: industrial controllers, workstations, equipment for arrangement of reactor control and protection systems and other equipment. Remark: The development started in 2003.

МSKU 3М

The МSKU 3М includes a functionally complete set of hardware and software allowing composing I&C systems in accordance with the requirements of a specific project and with observance of principles of a single failure, independence, a safe failure, diversity, determinancy of modes of operation.

The hardware of the МSKU 3М (programmable industrial controllers with different safety classes and redundancy degrees; industrial workstations with different functional purpose; switching cabinets; devices for communication with operators’ panels; signal converters; power supply devices, etc.) was developed based on an components of leading world manufacturing firms. The basic components of I&C systems are programmable industrial controllers of the MSKU 2, МSKU 3 series.

The software of the MSKU 3М includes the following:

- real-time system software (SW);

- communication SW;

- SW of operator stations;

- SW tool to prepare, debug and support application SW;

- Instrumental and diagnostic SW.

Download...

« Hide

An article was published in the journal “Nuclear and radiation safety” 2005, No. 01 “Neutron flux monitoring system for WWER-1000 reactors: safety assurance and assessment”.

Download...

An article was published in the journal “Nuclear and radiation safety” 2005, No. 04 “Concept of modernization of in-core monitoring systems for WWER-1000 of Ukrainian NPPs”.

Download...

An article was published in the journal “Devices” 2005, No. 12 “Severodonetsk “Impulse” today”.

Download...

2006

A catalog “Highly-reliable instrumentation and control systems for technological processes for nuclear power engineering and other branches of industry” was published. It included descriptions of components of the МSKU 3М and systems based on them.

Download…

Staff and veterans celebrated the 50th anniversary of the enterprise.

The solemn celebration took place, where employees with families and enterprise’s veterans, as well as representatives of partner organizations and users of products by SRPA “Impulse” were present. Director Volodymyr Yelisyeyev made a solemn speech. Then numerous speeches-congratulations followed. After this a holiday concert took place. All employees received cash bonuses, those distinguished themselves were awarded honorary diplomas.

An excursion for the distinguished veterans took place at the site of “Impulse” the day before.

An anniversary booklet of the enterprise was published.

Download...

Collected articles “Instrumentation and control systems” confined to the 50th anniversary of SRPA “Impulse” were published. The articles considered the peculiarities of instrumentation and control systems (I&C systems) for critical facilities, gave examples of practical implementation of software and hardware of I&C systems, considered issues of certification, assurance of reliability, survivability, production technology of I&C systems.

Download...

Since 2006, developments and supplies of the following systems to NPPs of Ukraine (within the Concept of Safety Upgrade for Operating NPP Power Units), RF and Armenia started based on the MSKU 3M

- AKNP-IF neutron flux monitoring systems (manufactured from 2006 till 2016);

- CRDS-440, CRDS-1000 reactor facility control rod drive systems (from 2006 till 2014);

- Boron concentration monitoring systems based on an NAR-I neutron solution analyzer (from 2007 till 2013);

- Digital normal operation control systems (from 2008 till 2013);

- “Black box” systems to register important parameters of NPP power unit operation (from 2008 till 2014);

- Centers for support of operators in emergencies (from 2008 till 2013);

- Reactor complex diagnostics systems (from 2008 till 2013);

- Systems to monitor emergency “Coolant leak from the primary circuit to the secondary one” (from 2009 till 2013);

- Digital technological safety control systems (from 2010 till 2013).

Download...

2007-2008

SRPA “Impulse” won one of the lots of the international tender held by the European Commission under the “Tacis U1.04/05A” project for supply of the neutron flux monitoring system to Khmelnitsky NPP.

In 2008, after successful acceptance testing with the participation of specialists of EBRD, the AKNP-IF neutron flux monitoring system was commissioned at power unit 1 of KhNPP.

An article was published in the journal “Nuclear and radiation safety” 2007, No. 01 “AKNP-IF neutron flux monitoring system: peculiarities, safety assurance and assessment”.

Download…

SRPA “Impulse” won the international tenders conducted under the modernization program for KhNPP-2/RNPP-4 after start-up financed out of proceeds of the credit managed by the EBRD:

- Complex diagnostics system for KhNPP-2, RNPP-4;

- “Black Box” system to preserve information in the beyond-design accident conditions for KhNPP-2, RNPP-4;

- System to control emergency “Coolant leak from the primary circuit to the secondary one with the equivalent section Dy100” for KhNPP-2, RNPP-4.

Works were performed within the time and in the scopes corresponding to the contracts.

In October 2008, the meeting of the coordination and expert council for NPP I&C systems under NNEGC “Energoatom” took place at SRPA “Impulse”. The members of the coordination and expert council saw the latest developments: CRDS-1000, I&C system of NOS RO, etc.

Link to the message...

2009-2011

The fourth-generation platform - МSKU 4М was developed: industrial controllers, workstations, equipment for arrangement of reactor control and protection systems and other equipment.

Based on the МSKU 4М the following is manufactured and commissioned at NPPs of Ukraine (within the framework of the Complex (Consolidated) Safety Upgrade Program for Ukrainian NPP Units), Slovakia, Bulgaria:

SRPA “Impulse” won the international tender held by the European Commission under the Instrument for Nuclear Safety Cooperation program (EuropeAid/127088/D/SUP/AM project) for supply of boron concentration and neutron flux monitoring systems for power unit 2 of Armenian NPP.

In 2010, after successful acceptance testing with the participation of specialists of the EBRD and Armenian NPP, the systems were commissioned at power unit 2 of NPP.

IА-4/3, IА-4/4 smooth start-up automates were supplied to Kozloduy NPP (Bulgaria).

A catalog “Highly-reliable instrumentation and control systems for technological processes for nuclear power engineering” was published. It included descriptions of components of the МSKU 3М and systems based on them.

Download...

2012

A catalog “Highly-reliable instrumentation and control systems for technological processes for nuclear power engineering and other branches of industry” was published. It included descriptions of components of the МSKU 4М and systems based on them.

Download…

2013

A new generation of unified highly-reliable software and hardware for implementation of integrated railway automatics systems was created. On their basis new-generation railway automatics systems were developed and are manufactured:

Experts of the mission “IAEA review of digital instrumentation and control systems developed by SRPA “Impulse”” audited processes of creation and operation of instrumentation and control systems important for NPP safety. Based on the results of the audit, high quality of development, manufacturing, testing and support of operation of the systems were noted, the systems conform to the corresponding sections of the IAEA Safety Guide NS-G-1.3.

In August of 2013, NNEGC “Energoatom” held the meeting of the coordination and expert council for NPP I&C systems at the site of SRPA “Impulse”. The issues of implementation and operation of new equipment for I&C systems of power units with WWER-type reactors were discussed during the meeting.

The members of the coordination and expert council visited the production shops, the experimental and research facilities, the testing laboratory and the enterprise’s museum.

Link to the message...

An article was published in the journal “Nuclear and radiation safety” 2013, No. 04 “NPP instrumentation and control systems manufactured by SRPA “Impulse”. State, prospects”.

Download…

2014

A tutorial “MPC-U and MAB-U microprocessor train control systems” was published. It gives main ideas and principles of construction of MPC-U microprocessor interlocking systems, MAB-U automatic block signalling and power supply systems. Characteristics, composition and descriptions of components are given.

Download...

2015

SRPA “Impulse” won the tender held within the implementation of the “Complex (Consolidated) Safety Upgrade Program for NPP Units” project using credit funds of EBRD/EURATOM for supply of a complex diagnostics system of a reactor facility and a primary pipelines displacement monitoring system for three power units: RNPP-3, KhNPP-1, SUNPP-3. The partners of “Impulse” in the project implementation – French and German company Framatome and Slovakian firm Vuje.

Link to the message...

Works were performed within the time and in the scopes corresponding to the contract with SE “NNEGC “Energoatom”.

Remark: Till 2018, SRPA “Impulse” won fifteen similar tenders for supply of instrumentation and control systems to Ukrainian NPPs.

2016

On 23 September 2016, the solemn celebration of the 60th anniversary of SRPA “Impulse” took place in the Ice Palace of Sport. Employees with families and enterprise’s veterans were invited to the celebration. All employees received cash bonuses, those distinguished themselves were awarded honorary diplomas. Chairman of the Supervisory Board Volodymyr Yelisyeyev made a solemn speech. The people gathered were congratulated by Chairman of the Lugansk Regional State Administration and Mayor of Severodonetsk.

Then a holiday concert with the participation of Ukrainian entertainment stars took place.

An excursion for distinguished veterans took place at the site of “Impulse” the day before. After the excursion, the veterans met Volodymyr Yelisyeyev and key specialists of “Impulse”. The veterans received holiday presents.

Link to the message...

An article was published in the journal “Nuclear and radiation safety” 2016, No. 03 “Experience of implementation of safety and normal operation control systems for NPP power units”.

Download…

In November 2016, a meeting of the Council of Chief Engineers of NNEGC “Energoatom” was held at the site of PJSC “SRPA “Impulse”. The management and the specialists of SRPA “Impulse” informed guests on the enterprise’s experience in design, manufacture and commissioning of highly-reliable instrumentation and control systems for nuclear power engineering and railway transport, current and prospective developments.

Link to the message...

2017

In May 2017, the meeting of the coordination and expert council of specialists in issues of I&C systems under SE “NNEGC “Energoatom” was held at SRPA “Impulse”.

The members of the coordination and expert council saw all stages of the complete production cycle for I&C systems at SRPA “Impulse”: visited the production workshops and areas, the experimental and research facilities, the testing center. The participants of the coordination and expert council noted high professionalism and well-developed production standards.

Link to the message...

2018

SRPA “Impulse” successfully completed the project on arrangement of the Beskid Railway Tunnel, namely: development, manufacture and successful commissioning of the microprocessor interlocking system that controls train traffic on Beskid Railway Station and Beskid Tunnel. MPC-U executes all train traffic monitoring and safe control functions. The system has an international certificate of meeting the SIL4 safety integrity level of the CENELEC standard.

Link to the message...

Representatives of the EBRD successfully audited execution by “Impulse” of contracts within the framework of implementation of the measures of the Complex (Consolidated) Safety Upgrade Program for Nuclear Power Plant Units (CCSUP). Based on the results of the audit, it was noted that the audit tasks had been implemented in a complete scope.

Link to the message...

SRPA “Impulse” within a consortium won the international tender for supply of the microprocessor interlocking system to Sindel Station (Bulgarian railway). Partners of “Impulse” in the project implementation – Bulgarian companies “Gigastroy”, “Innovo Development Bulgaria” and a Swiss company “BAER Bahnsicherung AG”. In connection with this, a kick-off meeting as to the project implementation took place at the site of SRPA “Impulse”.

Link to the original article...

An updated catalog “Highly-reliable instrumentation and control systems for technological processes for nuclear power engineering” was published. It included descriptions of components of the МSKU 4М and systems based on them.

Download...

A catalog “Automatics systems for railways” was published. It included descriptions of components of the railway signalling software and hardware and systems based on them.

Download...

.JPG)

.JPG)

.JPG)