PROJECT-ARRANGED POWER SUPPLY SYSTEM OF MEDIUM AND LARGE STATIONS (PKSEP)

PKSEP is designated for power supply of relay or microprocessor based interlocking devices of medium and large stations, at railway sections with any traction type.

|

Main functions

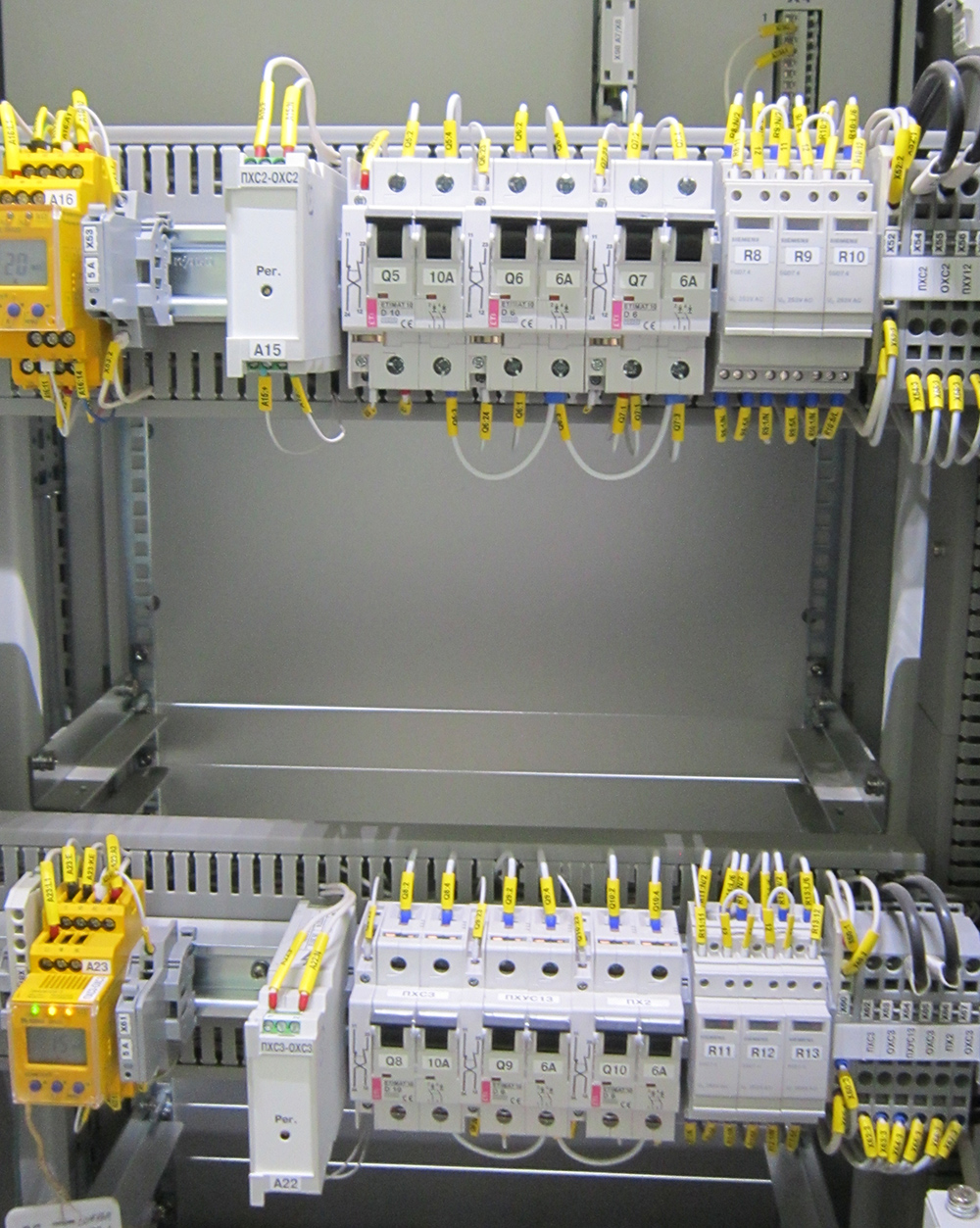

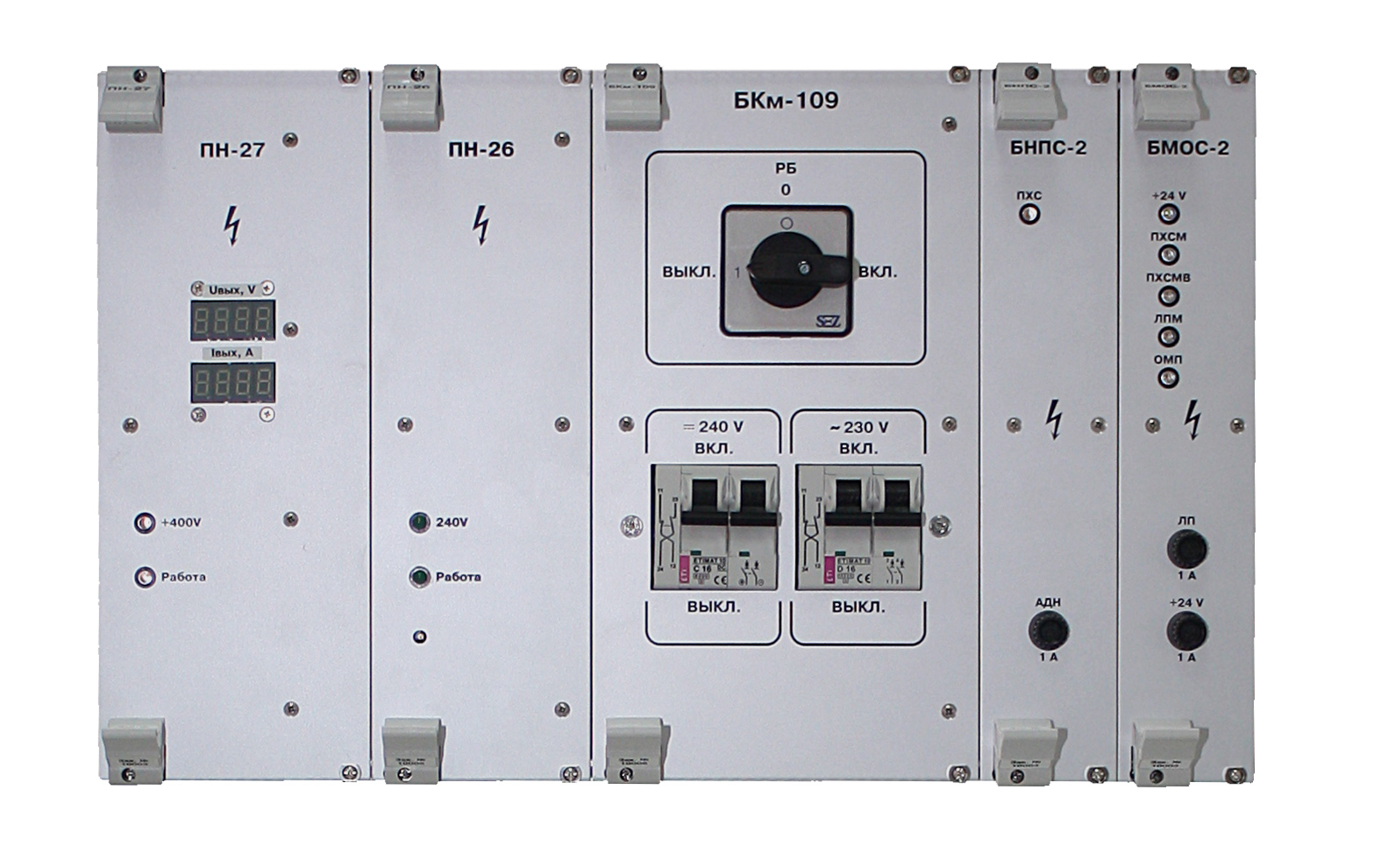

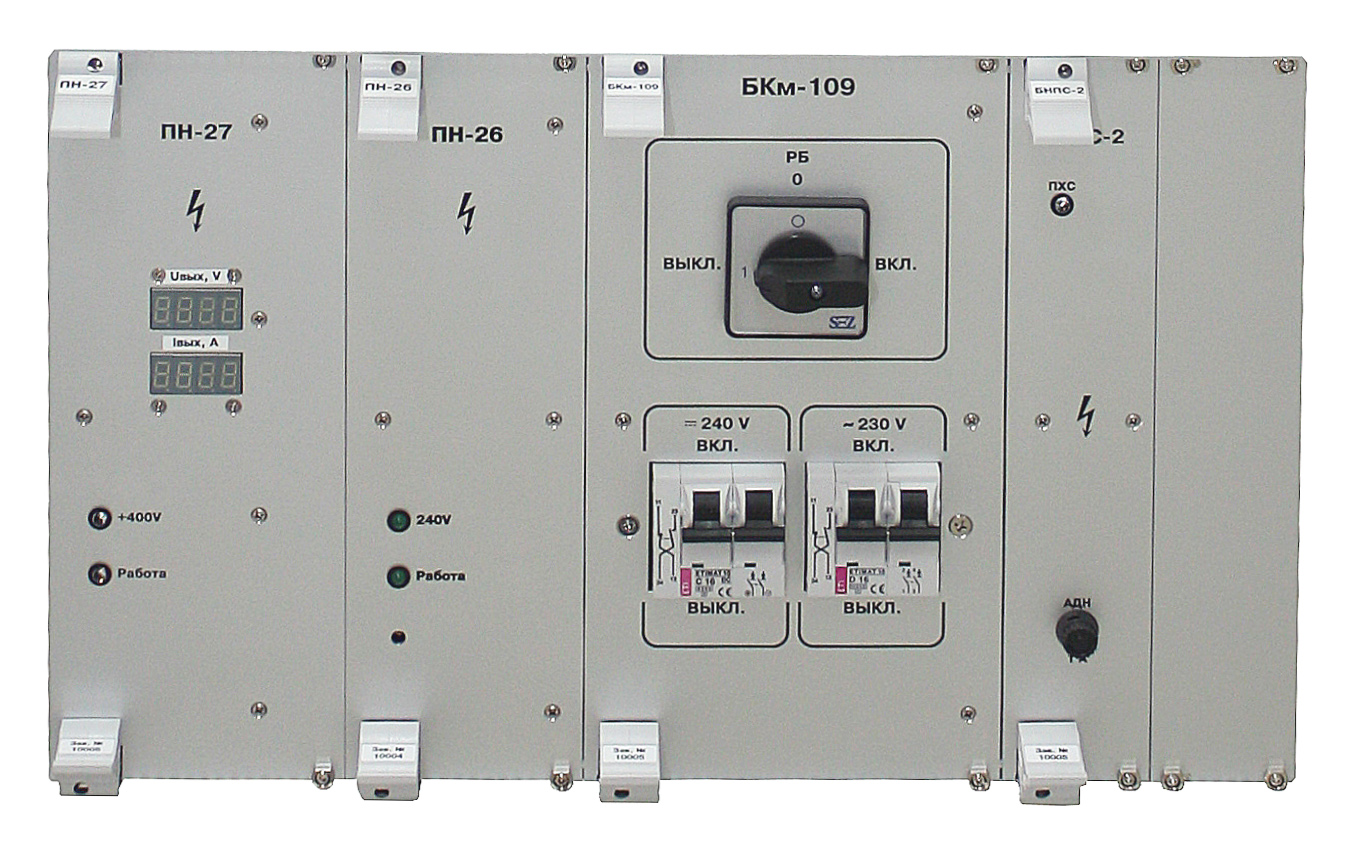

Composition PKSEP includes the following devices:

It is possible to compose two main types of power supply systems:

Power supply backup time, depending on AB capacity, is from 10 minutes to 8 hours. Rated load capacity of the system is:

|

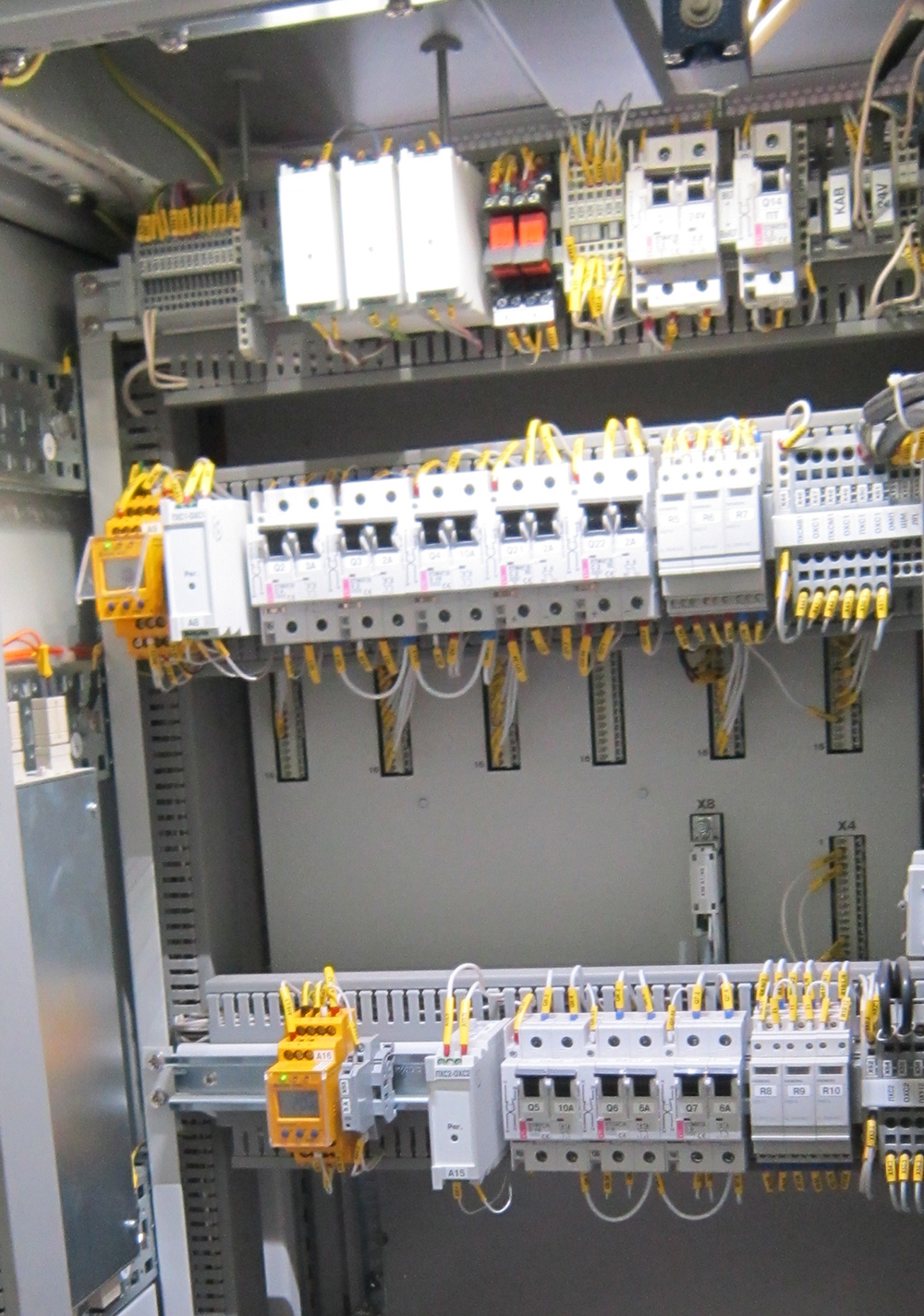

power supply cabinet |

|

|

|

|

||

| ShSt with redundancy | ShSt without redundancy | |||

System advantages

- design arrangement and scalability – allow designing a power supply system with the parameters required for a specific station;

- has been developed in accordance with the requirements of area «1520»;

- high “survivability” due to redundancy of main nodes;

- possibility of remote switching-off of input feeders, DGA, and AB with a “single button” when emergency situations or a fire emerge;

- possibility of manual selective switching-on/ switching-off of feeders;

- a built-in microprocessor based system monitors and diagnoses power supply parameters and PKSEP hardware state recording the following parameters:

- resistance of insulation as related to “ground” in circuits of power supply for signals, track circuits, relay racks, panels, electric switch machines, heating of electric switch machines;

- voltage and current in each phase of input feeders;

- voltage in output circuits of cabinets forming a part of PKSEP;

- operability of units and devices, automatic switches, protective varistors, etc.;

|

|

|

|

||

Input panel |

ShD diagnostic cabinet |

ShVpR rectifying distribution cabinet |

||

- possibility to monitor quality and periodicity of maintenance based on archive data:

- DGA start on load with specifying its operation duration and recording feeder parameters;

- service of station’s AB with switching-off a charger, operation of main and additional chargers;

|

|

|

|

||

| ShTr transformer cabinet | ||||

|

|