Surface mounting of printed circuit boards (a large-scale automatic line for surface mounting)

The automatic line for surface mounting has been assembled based on the following:

- an LP1L automatic device for screen printing (Samsung);

- an SM421 installer of surface mounting components (Samsung);

- a convection melting oven (SEHO GoReflow 2.3);

- loaders and unloaders with intermediate conveyors.

Application of the soldering paste

Within the automatic line for surface mounting, the soldering paste is applied using the LP1L automatic device for screen printing (Samsung), the automatic device is equipped with the frame for stencils with stencils’ pneumatic tension (LPKF). The equipment allows applying the soldering paste in the automatic mode with the high speed, accuracy and repeatability.

Installation of surface mounting components

Surface mounting components are installed on the SM421 all-purpose automatic installing device (Samsung) with the productivity up to 21000 comp./hour by IPC9850. The automatic device operates with the components in different packaging (bands, sticks, pallets) and with the wide range of case sizes from chips 0201 to BGA 42*42mm, with boards with minimum dimensions equal to 65*60mm and maximum dimensions equal to 400*400mm. The automatic installing device assures accuracy of installation: chips ±50 µm, QFP ±30 µm.

Melting of the soldering paste

The soldering paste is melt in the SEHO GoReflow 2.3 seven-zone convection melting oven, the oven is prepared for the Pb-free technological process. The KIC Explorer seven-channel device to read heat profiles is used to monitor and adjust the soldering temperature mode.

Loading-unloading and moving of the printed circuit assemblies

The transport equipment manufactured by Samsung is used for loading-unloading, as well as for transportation of a printed circuit assembly along the automated line.

Storage of humidity-sensitive components

Humidity-sensitive components are stored in the DRY540EC dry storage chamber (Conco Antistatic).

Preliminary drying of humidity-sensitive components, if required, is carried out in an FD 240 drying cabinet (Binder).

Monitoring of the assembly quality of printed circuit assemblies

The HV5000TLC (NEXSCIEN) automatic optical checking system is used to monitor the assembly quality of printed circuit assemblies, this system allows to perform visual installation monitoring (destroyed, omitted, diametrically installed, and turned over components), soldering quality monitoring (short circuits, breaks, and solder overlaps).

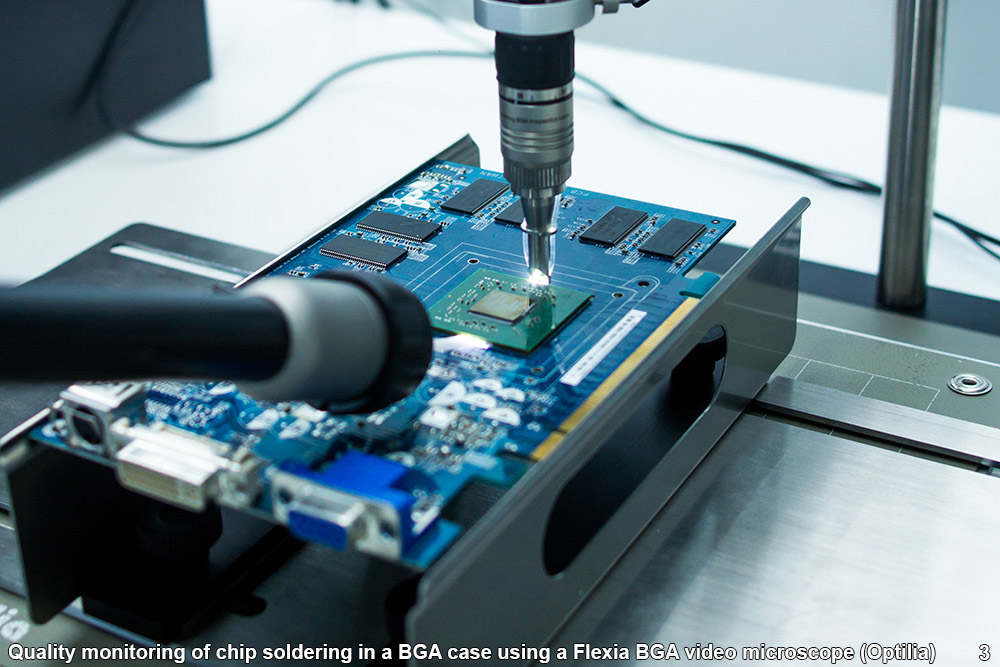

To monitor soldering quality and correctness of installation of microchips in BGA cases, the Flexia BGA optical inspection system (Optilia) with increase up to x100 is used.

Installation of microchips in a BGA case and repair of units with microchips in a BGA case

Microchips are installed in a BGA case using the SM421 automatic installing device (Samsung), this can also be done with the IR/PL 550A soldering-repairing station’s installer (ERSA). Units with microchips in a BGA case are repaired and balls of microchips in BGA cases are restored using the IR/PL 550A soldering-repairing station (ERSA).

Manufacturing of printed circuit assemblies in group (multipleх) half-finished products.

The following is possible: manufacturing of printed circuit assemblies with overall dimensions of a printed circuit board less than 65х60mm and with an irregular shape in group half-finished products with further separation of printed circuit assemblies from a half-finished product. At that, included printed circuit assemblies can fastened into a half-finished product by scribing or by using removable jumpers.

Scribed half-finished products are separated using a Maestro 3 installation (CAB).

Half-finished products with removable jumpers are separated using a DPF 200 depaneling system (Piergiacomi).