“ImproTRAIN-250” LOCOMOTIVE SAFETY SYSTEM

|

A modern on-board system to increase safety, to automate control of safety functions for locomotives and multiple-unit rolling stock. It can be used:

Main functions

|

|

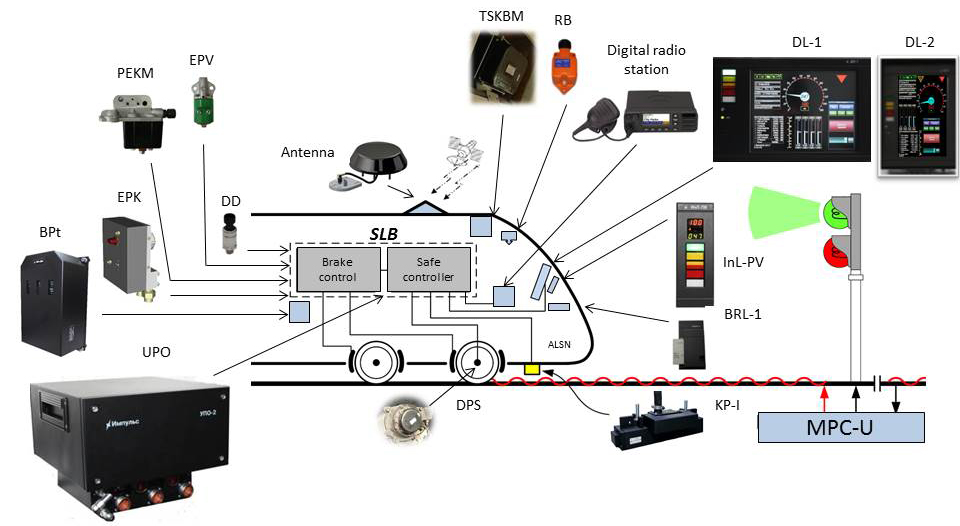

Composition

|

NAME |

PLACE OF INSTALLATION |

|

DL-1 (DL-2, DL-3) locomotive display |

Cabin |

|

InL-PV (InL-P) locomotive indicator of driver’s assistant |

Cabin |

|

BRL-1 registration unit |

Cabin |

|

KR-1 removable contactless registration cassette |

Cabin |

|

RB, RBS, RBP vigilance handle |

Cabin |

|

UPO-1 (UPO-2) secured redundant controller |

Body |

|

Electropneumatic valve (EPK), |

Body |

|

BPt power supply unit (three versions) |

Body |

|

DD pressure sensor |

Body |

|

DPS distance-and-speed sensor |

Box |

|

KP-I receiver coil |

Under a body |

|

SNS + antenna (a radio channel as an option) |

Deck |

Equipment that can be supplied additionally:

- a digital radio station;

- a radio channel brake control unit (PEKM).

Service equipment:

- an equipment for decoding recording cassettes;

- a device for shaping electronic cards;

- a console for deep check and diagnostics.

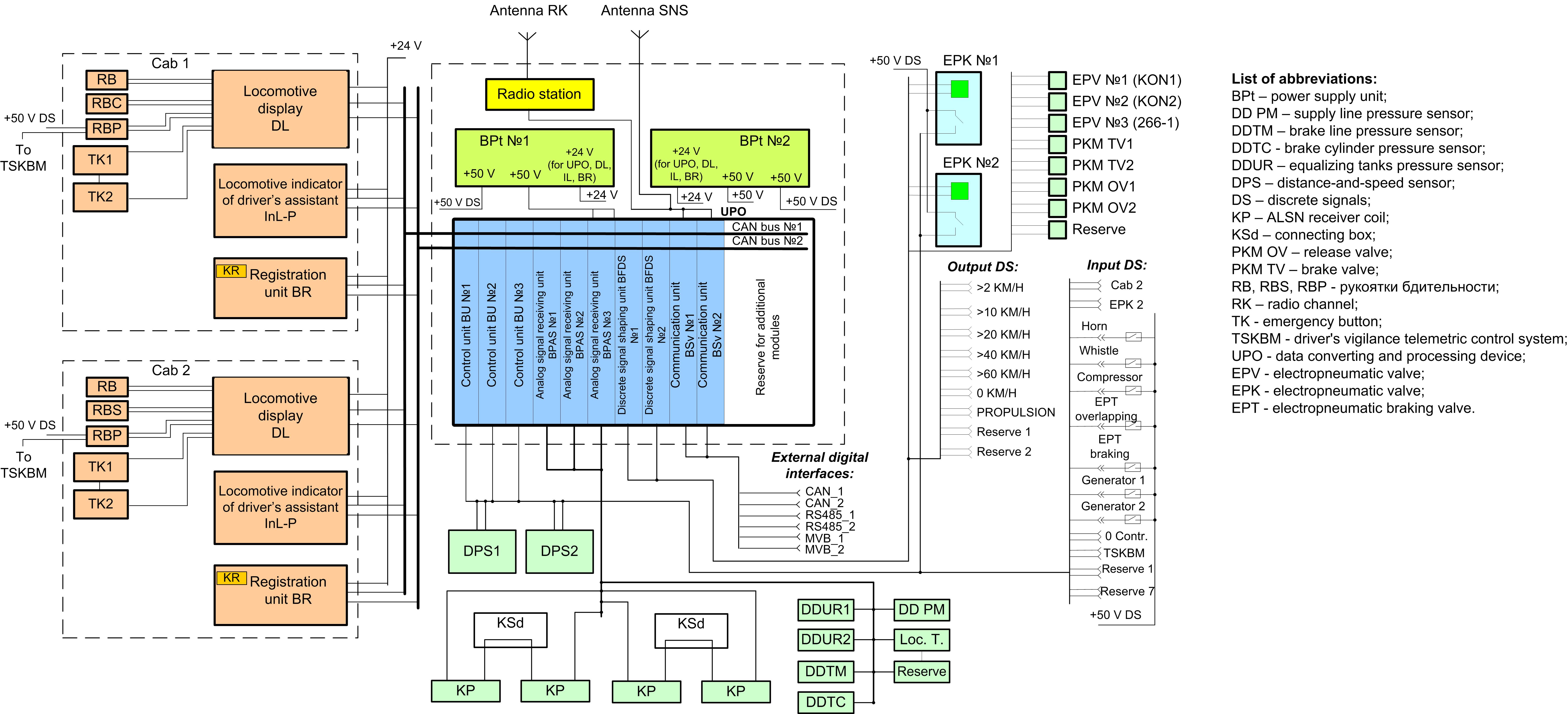

Structure

A modular structure allows composing the system with the configuration required for the customer. Interaction with the automatic braking control system (SAUT), driver’s vigilance telemetric control system (TSKBM), the automatic train operation system, etc. is carried out via an on-board local network.

Composition of the locomotive safety system

Structural scheme of “ImproTRAIN-250”

Reliability and functional safety of SLB are assured with the following:

- three-channel processing of input information by the “2oo3d” scheme with reconfiguring if one of channels fails (2оо3d → 2оо2d);

- generating output control signals in two diverse channels by the “2оо2d” principle;

- implementing multilevel safety:

- 1 level – monitoring permitted speed of a train based on the data recorded into an electronic card;

- 2 level – monitoring permitted speed specified with signals of ALSN, ALS-EN;

- 3 level – centralized control with the possibility to receive commands for immediate stop of a train via a radio channel;

- 4 level – monitoring based on internal algorithms and online data (state of an engine driver, mode of operation of PS, etc.);

- self-diagnosing using built-in simulators of model signals allowing diagnostic procedures without equipment dismantling from a locomotive.

System advantages

- 100% resistance to a "single failure" due to reconfiguration, which allows continuing movement in the safe mode without stopping;

- minimization of equipment (all functions as to receiving, processing, generating signals, including gateway functions, are implemented in one UPO construct);

- cyber security of the system meets the requirements of the corresponding ISO and IEC standards;

- possibility of departure diagnostics of the system and channels of communication with adjacent devices with the accuracy up to a module;

- use of permitted speed smooth change methods based on calculations taking into account movement dynamics and characteristics of a train composition (a locomotive type, a train weight, a brake type, a track plan, speed limitations, etc.);

- use of a removable contactless registration cassette protected against external impacts (including against deliberate distortion), assuring recording of the following during 72 hours:

- movement parameters, actions of an engine driver, and results of system diagnostics;

- frequency signals of ALSN with binding to coordinates for further analysis and diagnostics of field equipment;

- availability of a backup archive in a registration unit, which can be read if the main archive (cassette) is “unavailable”;

- availability of a set of service equipment is supplied for maintenance of operated devices;

- displaying extended diagnostic information on state of units and modules of the system on a screen of a locomotive display;

- possibility to increase quantity of input-output channels for analog and discrete signals, to configure a system in accordance with the Customer's requirements;

- availability of several versions of locomotive displays differing in overall dimensions and installation methods.